|

| Early Spark Coil Ignition |

| Author |

Message |

miro forest

Senior Member

Username: miro

Post Number: 681

Registered: 11-2001

| | Posted on Tuesday, March 05, 2013 - 09:41 pm: |

|

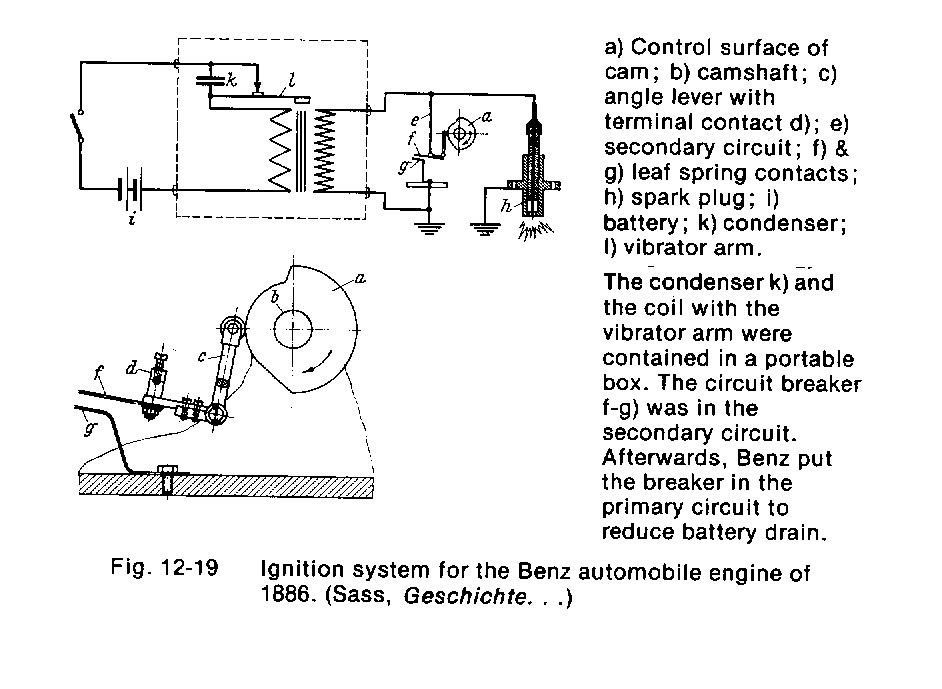

I've been reading a volume written by Lyle Cummins, son of the Cummins Diesel founder) about early internal combustion engines, and came across this reference to spark ignition used by Karl Benz in 1886.

The notable feature is that the cam driven contact shorts out the secondary winding until the right time and when it opens, a spark jumps across the gap in the spark plug.

The primary circuit is buzzing all the time.

Engine speed was a leisurely 250 rpm.

Eventually, they figured out this was not good for battery charge life, and redesigned it to what we use today in old engines, placing the cam driven contact in the primary circuit.

I don't know why they used the original configuration, Cummins does not speculate.

At the time hot tube ignitions were commonplace and more reliable than spark ignitions.

miro

|

Edward Fanuzzi

Member

Username: capt_ed

Post Number: 8

Registered: 12-2007

| | Posted on Wednesday, March 06, 2013 - 08:09 pm: |

|

i cant seem to find out any info why with respect to the question why did the engines use a constant spark device, a lever shorting the constant spark out untill it was ready to fire , had a thought, not sure, engineers might needing a spark, they just took a working battery spark generator off the shelf as its source, or thier thinking perhaps a longer steady spark to the cylinder made a more complete burn of the fuel, might of been a very low octane, my thoughts |

miro forest

Senior Member

Username: miro

Post Number: 682

Registered: 11-2001

| | Posted on Thursday, March 07, 2013 - 08:51 pm: |

|

Actually, today's most modern gas engines use the same technique, for(almost) the same reason.

They use multiple sparks to get the very lean mixture to fire.

On the old engines, the combination of the very high frequency of the "buzzing" and the relatively long dwell time when the timer contacts are touching plus low rpm means you'll get more than 1 spark. .

For example, with the engine running at 600 rpm, and the coil "buzzing' at 1 khz, and a dwell angle for the timer contacts of 10 degrees (most of them are more than this) , you'll get 3 sparks.

And if they nice hot sparks, the the mixture is more likely to ignite.

miro |

|

|

|

|