| Author |

Message |

searcher

Senior Member

Username: searcher

Post Number: 577

Registered: 10-2004

| | Posted on Monday, September 02, 2013 - 04:44 pm: |

|

Flywheel weight, diameter, and thickness was a highly engineered feature of the better grade of engines. I'm looking for a reference that discusses flywheel design. I think I recall reading an article on the subject in an early boating magazine like The Rudder or MotorBoat but I cannot find the article now. Any ideas would be appreciated. |

bruce

Senior Member

Username: bruce

Post Number: 400

Registered: 07-2002

| | Posted on Monday, September 02, 2013 - 11:43 pm: |

|

Fay Bowen stated that the thin but large diameter wheels were prefered in 1905 but a smaller diameter thicker flywheel was available as an alternative presumably for a lower center of gravity |

bcm

Senior Member

Username: bcm

Post Number: 52

Registered: 11-2009

| | Posted on Tuesday, September 03, 2013 - 08:29 am: |

|

Google: Gas Engine Design Charles Lucke

Can be read on line or POD copy purchased

Flywheel design calculations starting page 234 |

searcher

Senior Member

Username: searcher

Post Number: 578

Registered: 10-2004

| | Posted on Monday, September 09, 2013 - 09:38 pm: |

|

Bruce and BCM,

Thanks for the comments.

I read through Lucke's treatise on flywheels. It was quite informative. Thank you for providing the reference. Forty five years ago and fresh out of college I would have had the get up and go to run through the calculations but those days are gone.

Lucke states that some approachs to determining flywheel parameters rely on empirical data gained from studying functional engines. That is about my speed these days. The engine I need to make a flywheel for is just a bit of a thing - it has a 2.75" bore and about a 3.75" stroke. If anyone has an engine of about the same bore and stroke, I would appreciate knowing the flywheel diameter, rim thickness, and rim depth. For what little the engine will ever run, I'm not going to worry too much about precision. |

bartropr

Senior Member

Username: bartropr

Post Number: 67

Registered: 06-2006

| | Posted on Tuesday, September 10, 2013 - 03:28 pm: |

|

The flywheel on my Lozier which is 3.5"bore x 3.5"stroke has a flywheel which is 13" diameter x 4" face, so is very heavy! The only way I can lift it is with the flywheel off the engine. You can see pictures of in in the "Lozier in the UK" |

searcher

Senior Member

Username: searcher

Post Number: 614

Registered: 10-2004

| | Posted on Thursday, April 10, 2014 - 12:36 am: |

|

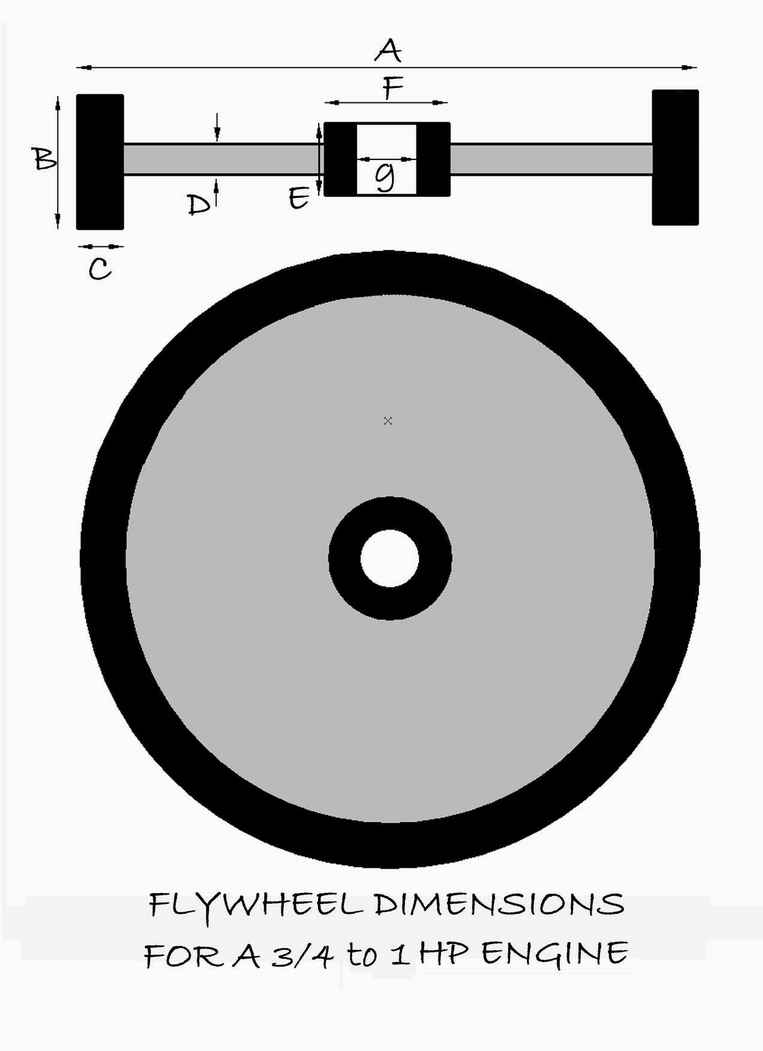

I haven't been able to find a suitable flywheel so I am going to have one made. I sure would appreciate the effort if three or four people would provide the dimensions of the flywheel on their 3/4hp to 1hp engine. The attached drawing indicates the dimensions I need. Thanks.

|

bcm

Senior Member

Username: bcm

Post Number: 55

Registered: 11-2009

| | Posted on Thursday, April 10, 2014 - 10:16 am: |

|

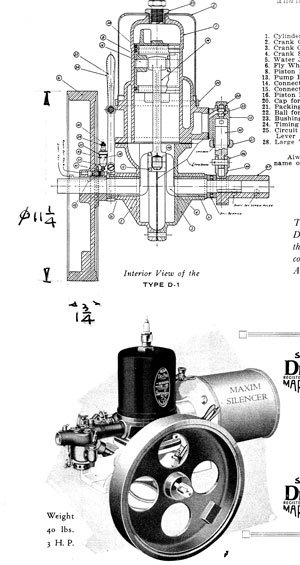

Silent Dispro Copper Jacket engine is 2 7/8" B X 3" S, about same output as your engine.

Attached image shows flywheel. I scaled dimensions.

regards

Barry

|

motorcanoe

Advanced Member

Username: motorcanoe

Post Number: 45

Registered: 06-2013

| | Posted on Thursday, April 10, 2014 - 03:05 pm: |

|

Contact: [email protected]

He has a casting pattern for the above referenced flywheel or a Waterman K1. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 905

Registered: 07-2002

| | Posted on Thursday, April 10, 2014 - 11:01 pm: |

|

This is small Detroit Auto Marine, about 9". I made a pattern and had some cast, the pattern was heavier in the rim to make it universal, it can be cut down to the 9" OD. We have one left, can send you a flywheel or the pattern.

|

searcher

Senior Member

Username: searcher

Post Number: 615

Registered: 10-2004

| | Posted on Saturday, April 12, 2014 - 08:56 pm: |

|

BCM, Motorcanoe, Ernie, and JB,

Thanks for the responses. I am finding exactly what Bruce mentioned back in September in this thread, i.e., some manufacturers preferred flywheels that were thin but had a large diameter while others preferred flywheels that were thick but had a smaller diameter.

A 9" to 9.5" flywheel would look best on the engine. However, the shaft is only 0.840" in diameter and 1.27" long so there isn't much to work with. I may have to go to a larger diameter just to get a flywheel thin enough to mount properly. |

marion

Member

Username: marion

Post Number: 5

Registered: 03-2013

| | Posted on Thursday, April 17, 2014 - 07:12 pm: |

|

Name A, in B, in C, in D, in E, in F, in G, in Total-I, in^4 Weight, lbs. Rg, inDispro 11.25 1.75 0.59 0.3 1.2 2 1 46.28 15.74 4.03

Searcher-1 9.25 2 3 0.5 1.27 1.7 0.84 63.95 32.03 3.04

Searcher-5 9.5 2 3 0.5 1.27 1.7 0.84 68.92 33.43 3.14

Searcher-2 9.25 3 3 0.5 1.27 1.7 0.84 95.50 47.37 3.10

Searcher-3 9.25 3 3.5 0.5 1.27 1.7 0.84 97.87 50.18 2.96

Searcher-6 9.5 3 3 0.5 1.27 1.7 0.84 102.86 49.38 3.21

Searcher-7 9.5 3 3.5 0.5 1.27 1.7 0.84 105.67 52.45 3.07

Searcher-4 9.25 3.5 3.5 0.5 1.27 1.7 0.84 114.12 58.41 2.97

Searcher-8 9.5 3.5 3.5 0.5 1.27 1.7 0.84 123.21 61.04 3.08

Lozier 13.00 4.00 2.75 0.84 2.59 2.59 1.18 311.97 103.60 4.58

The table above list the geometric properties and weights of some cast iron flywheels; Dispro less four web holes, Searcher �what-if� designs with constraints, and Lozier. Note the value of I, the moment of inertia, flywheel weight, and Rg, radius of gyration. As I is increased, more kinetic energy is stored in the flywheel resulting in reduce fluctuations in rotational speed. However, the weight also is increased. Rg is a relative number indicating how well the cross-sectional area is distributed to produce I. Both the Dispro and Lozier are good designs, but still very different applications where the small Dispro does it with a thin web and the Lozier does it with a very thick rim.

Thickness of the web is also limited by differential cooling and induces radial tensile stresses. Something that cast iron does not like and will crack. Hence, the early use of craved spokes in flywheels, but now these should really only be run in one direction of rotation . . . not good for two-cycle marine engines without a reversing gear.

If anyone wants to do their own what-if analysis on these types of flywheels, I�ll send you an e-mail attachment to the Excel spreadsheet. |

rbprice

Senior Member

Username: rbprice

Post Number: 458

Registered: 11-2001

| | Posted on Wednesday, April 30, 2014 - 08:24 pm: |

|

Hello Marion - I would love to have a copy of your spread sheet.

I have a very good copy of the Lucke's book that I have been studying. Is your spreadsheet based on his equations?

Thanks very much.

[email protected] |