|

| Author |

Message |

rbprice

| | Posted on Wednesday, June 23, 2004 - 09:59 pm: |

|

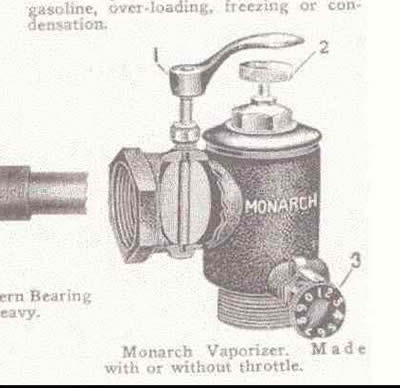

I have just purchased a Monarch mixer valve that has been badly repaired by someone.

Does anyone out there have one like the one in the attached picture [lower right corner] who could tell me the details of the adjustment on the end of the top knob marked 2 in the cut. It adjusts the spring force on the poppet valve but just how it was origionally configured is still a mystery to me.

Thanks

see picture in frame below. Andrew |

Ernie

| | Posted on Thursday, June 24, 2004 - 08:06 am: |

|

Bob,

Give me a call.

Ernie |

andrew

| | Posted on Thursday, June 24, 2004 - 10:13 am: |

|

Here is Bob's picture:

|

Richard Day

| | Posted on Thursday, June 24, 2004 - 07:17 pm: |

|

My experience with the #2 control is first make sure you have the phosphor bronze spring in correctly. The small end like in the Schebler Model D is at the control rod end and the wider spring area is on the valve in this case and on the air valve in the model D. If this is reversed there is no control over the lift on the valve. I would start out with a very light lift and use the needle valve #3 to control the mixture. If the engine were working under load then the #2 would have to exert more pressure to return the valve to the seat but at shows with the engine idling I think you really wont see any operational difference as long as the valve is returned to the seat promptly. Some mixing valves did't even have an adjustment. I often wonder if it was just a way to sell this valve over that valve. Keep in mind that these valve breath a lot better if they have a short say 6" nipple on the intake side. I got that from Joe Sydham who just died last week. The last of the great two stroke engineers I guess. We shall miss him here in Maryland. You could always get good advice from him on the old timers. To those of us who knew him he was a real peice of work!!! So long Joe. |

andrew

| | Posted on Friday, June 25, 2004 - 06:48 pm: |

|

Dick,

I am very sorry to hear that Joe Sydham died. He was a amazing guy with a wealth of skill and knowledge... and a nice guy as well. I visited his shop a couple of times and enjoyed sitting in front of the coal stove and hearing stories about the old days... |

Richard Day

| | Posted on Saturday, June 26, 2004 - 06:04 pm: |

|

Andrew, You were very lucky to have been in his shop even once was a treat. Twice I can only say he must have liked you. Very few people got inside the door much less twice. That shop should be picked up in once piece and put in a national museum. It is beyond beliefe. Right out of the late 19th century. Joe was always worried he would not have enough ZR head gaskets in case he needed one. The quality of his machine work was so good that he built the machines that calibrate steel rules we all use when other companys had failed. I shall miss him as he could answer questions that no other living person could when it came to early one lungers. |

rbprice

| | Posted on Saturday, June 26, 2004 - 08:40 pm: |

|

Thanks for the response Dick. I particularly liked the advice about a short intake pipe to help lift the valve off the seat.

I never knew Mr. Sydham but the loss of all that knowledge is always a troublesome thing to hear about.

Regards

Bob Price |

Robert

| | Posted on Monday, June 28, 2004 - 02:08 am: |

|

It sounds like a page could be devoted to this man, and that raises an idea: pages somewhere on this site devoted to some of the great old characters and craftsmen whose lives, work or interests were involved with old marine engines...of course I haven't done my engine pages yet...but, ah, well, you know how it is...! |

Richard Day

| | Posted on Monday, June 28, 2004 - 09:21 pm: |

|

I forgot to add a very important note on visiting Joe Sydham. Andrew mentioned the pot bellied coal stove in the corner of the machne shop. He didn't mention Joe always had a good supply of cold beer and before we got down to serious work we had to enjoy a brew or two. Most hospitable host and just enjoyable man to talk with. In the early days of radio Joe had a most powerful spark transmitter on the end of Long ISland and when spark was no longer tolerated Joe refused to shut down his rig so the FCC's predessors came and seized his transmitter for interferring with all the Navy and othe receiving station in the region.

His argument was he was there first and therefore they had no right to shut him down. "SPARK FOREVER" was the clarion call. |

andrew

| | Posted on Monday, June 28, 2004 - 10:49 pm: |

|

Dick,

One of the times I was there it was cold beer and a big cigar at 11:00 in the morning!

As I recall the floor of the shop was edge grain wood to absorb the blow if anything fell. The only other time I have seen that was in a pre-WWII machine shop in a big shipyard in Texas. Nice on your feet and nice on the tools...

I hope his relatives or the town lock up his shop so that it can be preserved intact.

Regards,

Andrew |

Richard Day

| | Posted on Tuesday, June 29, 2004 - 07:29 am: |

|

Don't forget the knob and tube wiring and pre WWI switch gear. The whole shop was driven by a Fuller and Johnson gas engine about 7 hsp I think. Joe wouldn't pay the price the power company wanted to supply power to drive his equipment. All flat belt drive. It just goes on and on. Don't know what is going to happen to it. Will keep you in the loop. |

|

|

|

|