|

| Author |

Message |

len traverse

New member

Username: laybacklenny

Post Number: 2

Registered: 12-2016

| | Posted on Tuesday, December 13, 2016 - 07:35 am: |

|

Hello guys & gals, just given a 8 Acadia witch has been laying outside for 10 years. The serial no 81369 .A few questions... Can you tell the year from the serial no.? What is recommended for un ceasing the piston? Will welding a 6 in crack in the cylinder hold?

Thanks Len |

Ernie

Senior Member

Username: ernie

Post Number: 2344

Registered: 01-2002

| | Posted on Tuesday, December 13, 2016 - 08:17 am: |

|

Len,

Here is some info.

http://www.oldmarineengine.com/discus/messages/3434/96223.html

Just use the search function located at the top of the page and you will find a ton of info on Acadia and old marine engines in general.

Enjoy

Ernie |

Ernie

Senior Member

Username: ernie

Post Number: 2345

Registered: 01-2002

| | Posted on Tuesday, December 13, 2016 - 08:28 am: |

|

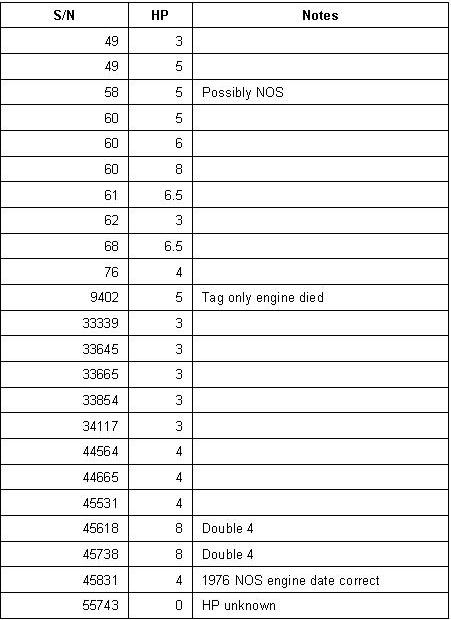

Here is a serial number list put together a few years ago.

|

Robert

Senior Member

Username: robert

Post Number: 815

Registered: 07-2003

| | Posted on Tuesday, December 13, 2016 - 11:12 am: |

|

Laying outside is often better than inside. If the engine was salt-water cooled read up here on rust in water jackets and what can be done about it.

No point welding any cracks shut as the rust scale will just blow it apart somewhere else, unless the crack was caused by freezing damage.

If the crack has weeping rust stains it's probably scale buildup that caused it.

A complete tear-down and rebuild is often the only way, and always the best way, to make it a runner again if the piston is stuck. Start by measuring the position of the piston with a stick through the spark plug hole.

If you can get the rod cap off through the side covers you can separate the cylinder, conrod and piston from the engine base and flywheel and work on it more easily.

If the piston is pushed up the rings will spring out over the top of the cylinder wall and at that point you have a nice anchor or yard ornament, unless it has an aluminum piston, in which case you could melt it out, perhaps.

You could try a tiger torch on the outside to warm the cylinder up enough to drive out some of of the moisture, blow some compressed air through the sparkplug hole for a while while doing so to help dry it out. When you think it's ready, pour in your favorite penetrating oil and let it sit for a few weeks. Adding a bit of air pressure via the sparkplug hole (3/4" NPT thread) can help force the oil down around the piston, but it can also just blow it all past the piston via the easiest route, so probably not worth it, unless you refill the cylinder afterwards.

Old timers would do tricky things like sitting the cylinder on its side, putting a round steel bar of the same dia. as the crank through the conrod 'hole' and building up wooden shims on both sides between the bottom face of the cylinder and the steel rod. Using dry wood of the right type, you can get enormous power of expansion when the wood is made wet and swells up, which would be achieved by standing the whole thing up in a pan of water as deep as the bottom face of the cylinder and letting nature take its course. Repeat as necessary with larger and larger wooden shims. A couple of pieces of 1" thick flat bar across the bottom of the cylinder flange on either side of the rod would help spread the load.

Some people have filled stuck pistons/cylinders with grease and pushed them out with grease guns, some have put rods down the spark plug hole and used hydraulic presses...sometimes just busting a hole through the piston in the process, especially if aluminum as I believe the later Acadias were.

Melting that sucker out might end up being your best option. Take stripped cylinder and bake it in a vertical position till the alu. runs out. Then you have to get the rings out without scoring the bore...

Think of the fun you can have in this hobby! Welcome!

|

len traverse

New member

Username: laybacklenny

Post Number: 3

Registered: 12-2016

| | Posted on Saturday, December 17, 2016 - 07:45 am: |

|

Thanks guy's will let you know how it goes

Len |

|

|

|

|