|

| projects from John in Australia |

| Author |

Message |

andrew

| | Posted on Wednesday, March 17, 2004 - 09:09 pm: |

|

John K. sent in the following:

Quote:Hello Andrew.

Attached are some pics of my projects that the group might like to see on the 'Boats with Engines' discussion board...

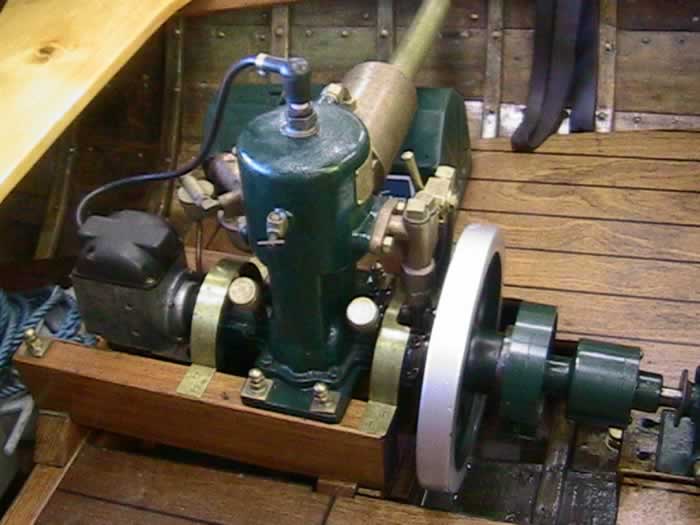

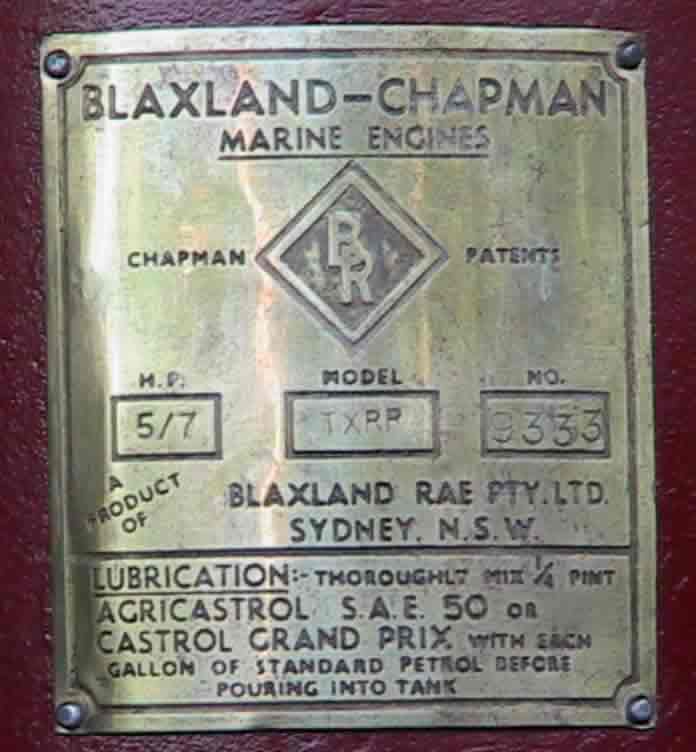

Attachments in order below - WHIMBREL is my current operating boat, Baldridge is the gearbox that Richard kindly gave the info on (not complete yet) to go into COMORANT, Blaxland is the engine I am currently working on (nearly finished), also to go into COMORANT, and COMORANT is the 'new' Chapman made launch, currently filling my garage, that I am planning to have finished for the trip down the Murray in 2007 (you can see some of the four split planks I neeed to replace!). The nameplate is on the Blaxland engine, and Vinco is the operating engine in WHIMBREL.

I hope everyone enjoys seeing some downunder projects.

I will learn how to resize to 50kilobytes and post some progress shots as appropriate. That will be good motivation to make some progress!

Thanks to all for the friendship and the great boatie site.

Cheers

John

|

John Kemister

| | Posted on Wednesday, March 17, 2004 - 10:30 pm: |

|

Thanks to Andrew for posting these for me.

I am still deciding whether to repaint the 16 footer in its original white and blue colours or to varnish. WHIMBREL looks very nice varnished, and they would make a great pair. The conservator in me likes originality, the artist likes varnished wood! It all depends how the hull cleans up as the previous owner had attempted to strip the paint using a blowlamp and you can see the bad burn marks. If they still remain I might have to paint below the waterline at least. I will move the transom forwards about 1 inch to get away from the bad 'split ends', and replace the four split planks. I may rerivet the hull as the copper nails and roves are about 50% corroded through. The motor has another conrod to replace the one that was bent and compressed 1/8 inch in another life, and I needed to sleeve the flywheel water pump eccentric as it was badly corroded. The engine is nearly operational. The best thing I have ever done is manufacture the two way tap on the water pump inlet on the Vinco so I can pump the bilges as necessary.

Cheers for now.

John |

Bruce

| | Posted on Wednesday, March 17, 2004 - 11:47 pm: |

|

I think most of the old hulls were painted sides because it was easier to patch up the inevitable dock rash from landing these old marine marine engine powered craft at reduced throttle or reversing on the spark. |

John Kemister

| | Posted on Thursday, March 18, 2004 - 05:17 pm: |

|

Hi Bruce. True. I have also just discovered burn marks under the white as well so it looks like it was repainted anyway sometime in the past. I cannot find any signs of another colour.

On the matter of 'reversing on the spark'. Blaxland gives instructions on doing this, and the engines may be designed for it, but the idea of stresses imposed by the instantaneous reversal of the large flywheel on the crankshaft and conrod if performed incorrectly gives me the horrors. That may be why the bronze conrod was compressed and bent sometime in the past? They are quite soft. That is one reason I am fitting the reversing gearbox. Any other thoughts on this process? |

Bruce

| | Posted on Thursday, March 18, 2004 - 08:35 pm: |

|

plump up any planking divits as much as possible with hot water or steam on bare wood. Sand smooth up to 100 grit and clean with mineral spirits. prime with a sanding/filler primer coat a couple coats to fill in the minute surface blemishes by sanding between coats. Build up your finish in thinned layers for maximum adhesion sanding between finish coats. Final job like plating only as good as the initial surface prep. |

poker casino74

Visitor

| | Posted on Monday, March 06, 2006 - 05:31 pm: |

|

poker casino poker 592 |

|

|

|

|