| Author |

Message |

jdheinzmann

New member

Username: jdheinzmann

Post Number: 1

Registered: 08-2009

| | Posted on Tuesday, August 18, 2009 - 11:18 pm: |

|

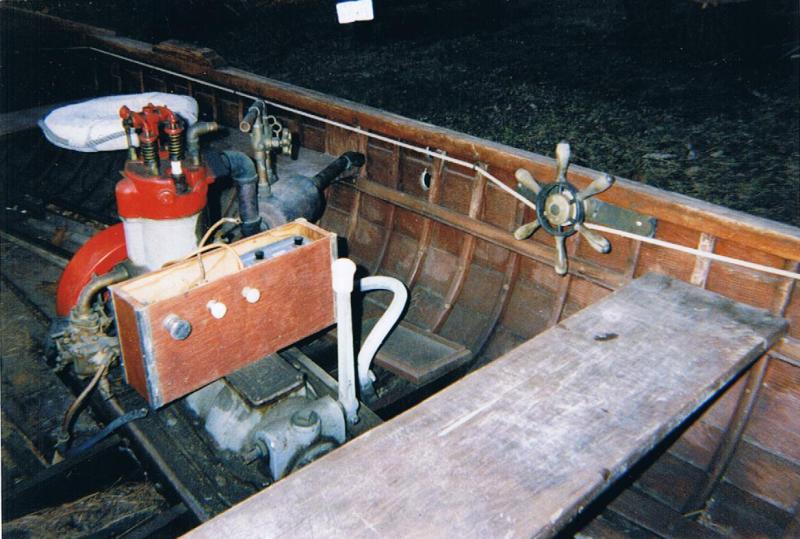

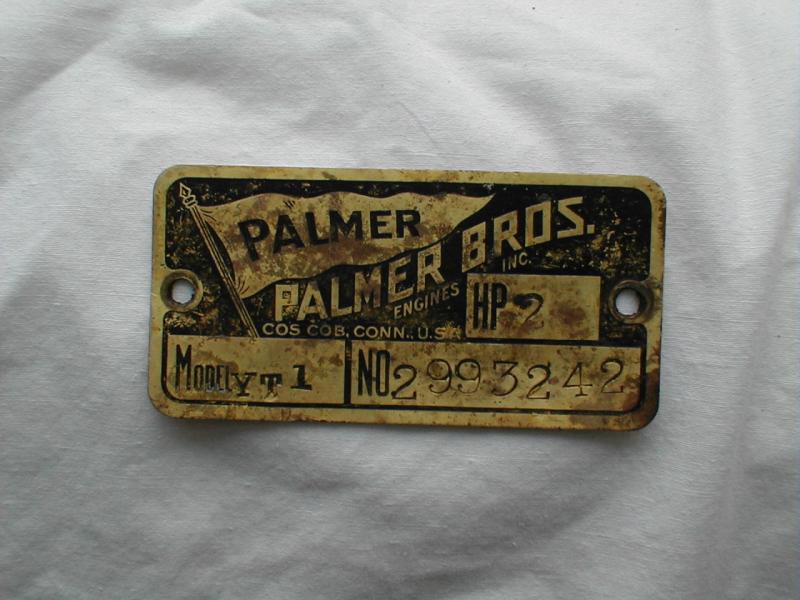

I was looking for Richard Day at the Mystic engine show last weekend and I ran into a couple of guys from this forum who shamed me into posting some information about my boat/engine project. This is a boat I bought from a friend about 10 years ago. His father got it in trade for a row-boat that he had made in the 50's or 60's. My friend zipped about in it in Alton Bay on Lake Winnipesaukee when he was a boy using an outboard engine. Later his father installed this Palmer YT-1 in it. In 1999, he took me in his runabout up to the Steamboat meet in Lees Mills. On our way back I mentioned that I had always dreamed of having a steam launch. He said "I have just the boat for you". I thought, "yeah, right." Sure enough, under a tarp was this beauty, trailer and all. So I bought it. I really wasn't planning on actually buying a boat but but this one was not to be passed up. I will get it running with this engine before deciding if I want to change to steam.

I registered the engine with Richard Day and he supplied me with a manual and a carb. rebuild kit. It runs well but doesn't idle well. I fixed all the induction leaks I could find. Now I am wondering if it might be a leak past the intake valve stem. It comes down to a nice idle but after maybe 8-10 seconds, it slows and quits. Any ideas?

I need to replace the gas tank. It was custom made to fit in the bow using galvanized steel. It is totally rotted out. I was thinking of making one out of copper. I'm not very interested in putting anything plastic into this boat. Any suggestions? Anybody who custom builds gas tanks?

Thanks! |

jdheinzmann

New member

Username: jdheinzmann

Post Number: 2

Registered: 08-2009

| | Posted on Tuesday, August 18, 2009 - 11:20 pm: |

|

Here are some more photos:

|

jdheinzmann

New member

Username: jdheinzmann

Post Number: 3

Registered: 08-2009

| | Posted on Tuesday, August 18, 2009 - 11:21 pm: |

|

And three more:

|

jdheinzmann

Member

Username: jdheinzmann

Post Number: 4

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 08:20 am: |

|

The restoration of Bay Girl got interrupted for a few years while my wife and I focused on our house restoration. With that largely behind us, I have again lowered her hull from the ceiling of the old barn and started in anew. Here are a couple of photos of the project from 2003.

Here she is, stripped and ready for repairs:

Eight ribs were cracked and needed repair:

Laminating one of the new rib pieces:

|

kerrigan

Member

Username: kerrigan

Post Number: 15

Registered: 06-2008

| | Posted on Wednesday, August 19, 2009 - 09:36 am: |

|

I have a copper fuel tank that might suit your purpose. It's 8 inches in diameter and 19-1/2 inches long. The original flush mounted filler fitting is also available along with a brass fuel filter.

These items were removed from a 1957 wooden 25' Dutch Treat sloop along with a Palmer 6 horsepower BH-25 engine complete with drive gear and prop. It too can be had. Photos will be sent by e-mail on request. |

richardday

Senior Member

Username: richardday

Post Number: 787

Registered: 11-2003

| | Posted on Wednesday, August 19, 2009 - 03:26 pm: |

|

Great to see it John. Wish I could have been at the show. Missed seeing the whole gang. My thoughts on the idle problem is typically it is a matter of adjustment of needle valve and idle set screw. Most YT-1 idle down very well. Guess I would clean the carburetor and make sure the bowl vent hole is not plugged with crud. To clean the inlet valve remove the brass plug where the fuel inlet is and take a small tube which you can push into the inlet area and blow any crud out from the are. just blowing into the area doesn't do anything but pack things tighter. The air jet has to bottom out in the inlet and that should blow any crud out. Not knowing the angle of the engine in the boat it appears the carburetor may be tipped too far counter clockwise. Should be more or less level under way. You bend the copper inlet manifold to get the desired angle. |

rendo

Member

Username: rendo

Post Number: 25

Registered: 08-2006

| | Posted on Wednesday, August 19, 2009 - 10:26 pm: |

|

I understand that copper may not be lawfully used as a gas tank in boats in the US. In Ocean County, NJ, there are at least two companies that make totally custom aluminum gas tanks for boats. Not too terribly expensive either. Atlantic coastal welding in bayville, nj, made the tank for my Shepherd, nice job. They won't put a drain in the bottom per Coast guard rules.

John |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 5

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 10:33 pm: |

|

Wow! Any idea what the issue with copper fuel tanks is?

Thanks.

JD |

miro

Senior Member

Username: miro

Post Number: 387

Registered: 11-2001

| | Posted on Wednesday, August 19, 2009 - 10:56 pm: |

|

Mike C and I were the two guilty parties at Mystic.

I'm so glad you've posted the pictures. It surely is a project that needs to be taken to completion soon.

Take Dick' advice on the engine.

I found that a competent sheet metal shop can duplicate the tank if you show them the original.

I couldn't quite make out the engine mounting arrangement, but please make sure you've got as beefy an engine bed as you can make - more is better. Two sturdy bulkheads fore and aft of the engine will help stiffen the engine mounting and damp the vibrations.

As for the outside seams, it's OK to squeeze on a bead of Sikaflex polyurethane bedding compound before you paint the hull. It make be a bit messy but I smooth the bead with a nitrile gloved finger tip.

The bedding compound is sort of like a flexible gasket as the wood swells and shrinks over the years.

Miro |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 6

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 10:57 pm: |

|

Hi, Richard. Thanks for your reply. I am doing this from memory now as the last time I ran the engine was in 2003. I know everything was clean then because I had taken the carb all apart and cleaned everything and replaced whatever needed replacing. I hadn't thought about the carb angle though. You are right, it looks far from level in my pictures. I wonder if I tilt the engine to represent the mount angle or at least to make the carb level it will run better. I'll keep that in mind the next time I run it.

Thanks again!

John David |

rendo

Member

Username: rendo

Post Number: 26

Registered: 08-2006

| | Posted on Wednesday, August 19, 2009 - 11:29 pm: |

|

On the copper tank. My recollection is that the gasoline additives today break down and will consume the copper. Not like the old days when there was gasoline in the gasoline.

John |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 7

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 11:31 pm: |

|

Ah, yes, Miro and Mike,

Thanks for the nudge to post here. Already the feedback has been wonderful. And nothing like a little social pressure to get motivated.

Indeed, years back, I was speaking to a boat builder in Maine and he suggested I do the same thing between the planks but with 3M 5300 (I think it was, but I only see 5200 listed at the JD site now). In any event, I did what he said and it is all sealed up now. I am a bit of a purist and I have been second guessing myself ever since. It is good to hear you make a similar suggestion.

I think the engine mounting was good and beefy. But I will pay special attention to that when I bring it back down from the barn and contemplate reassembling it.

There was/still is an aweful lot of engine oil soaked into the hull. I've been thinking how nice it would be to build a pan into the bedding underneath the engine, maybe made out of copper, to collect all the drippings. That may be wishful thinking though. I imagine there will be times there will be lots o water sloshing around the bottom of the boat, flooding anything I put there.

You are right, I've got to get this thing into the water soon so that I can get better calibrated on all this. I suppose I should stop fussing so much trying to get everything so perfect and put it in the water just for the learning.

Thanks!

JD |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 8

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 11:35 pm: |

|

John,

I wonder if I need to worry about the ethanol in my Palmer. Are there precautions to take for that too? Counter additives I should be using?

Does this mean I shouldn't use a copper fuel line either? Boo hoo! I really like copper!

JD |

rendo

Member

Username: rendo

Post Number: 27

Registered: 08-2006

| | Posted on Wednesday, August 19, 2009 - 11:56 pm: |

|

I am struggling with the same problem in my 1911 Franklin Model D touring car. The modern gasoline has really done a number on the original copper tank. I am told by a chemist that today's ethanol is "wet" meaning that it actually has water molecules in it. This will corrode any copper tank. Ethanol has the tendency to draw moisture out of the air. Big problem in a nice damp boat left in the water over night. Marine fuel does not have ethanol in it but who wants to pay for fuel at the dock? I think in the long run, we are much better off not using copper.

John |

kerrigan

Member

Username: kerrigan

Post Number: 16

Registered: 06-2008

| | Posted on Thursday, August 20, 2009 - 09:28 am: |

|

I haven't priced fuel at the dock lately but how much fuel will a YT-1 consume in a days run? What about the fuel lines and fittings? Stainless steel is difficult to bend and plastic is combustible. Stick with copper. If you can't afford fuel you should not be messing around with boats. |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 9

Registered: 08-2009

| | Posted on Thursday, August 20, 2009 - 09:44 am: |

|

Well, that solves it for me. If all I have to do is buy my gas from a marina, I will happily suffer that "inconvenience". The question is, can I get away with a copper tank without being busted for it. And to Spence's question, how much fuel should I expect the YT-1 to consume in a day? I need to know so I can properly size my tank. The old one was huge! I'd guess 15 gals or so. That probably served the prior owner well when he had an outboard motor on it. But for the YT-1, I can't imagine I'd need more than 5 gallons. I mean, I can do all the math assuming a conversion efficiency for the engine (low I expect) and the heating value of the fuel but I'd like to hear what practical experience anyone here has to offer.

Thanks.

JD |

rendo

Member

Username: rendo

Post Number: 28

Registered: 08-2006

| | Posted on Thursday, August 20, 2009 - 12:30 pm: |

|

The issue is not the ethanol, it is the other chemicals in the reformulated gasoline. These attack the copper, but if you drain it after you use it you could use copper but for the Coast Guard prohibition.

John |

kerrigan

Member

Username: kerrigan

Post Number: 17

Registered: 06-2008

| | Posted on Thursday, August 20, 2009 - 12:56 pm: |

|

What exactly are the Coast Guard prohibitions? |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 10

Registered: 08-2009

| | Posted on Thursday, August 20, 2009 - 06:24 pm: |

|

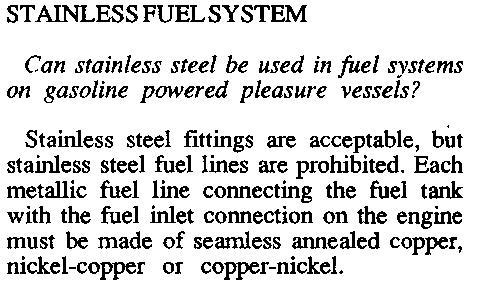

I just found this here: http://www.uscgboating.org/recalls/pdfs/bscscan68b.pdf

Things are looking brighter for copper in my boat.

JD |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 11

Registered: 08-2009

| | Posted on Thursday, August 20, 2009 - 06:57 pm: |

|

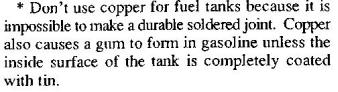

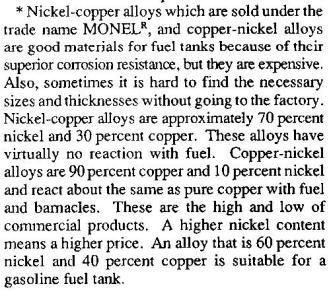

This boating safety circular is a jackpot. http://www.uscgboating.org/recalls/pdfs/bscscan64d.pdf.

They don't like copper because soldered seams are weak:

So, I can rivet and silver solder the seams and get the inside tin plated. I like that.

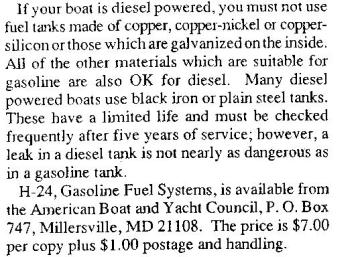

On the other hand, they seem to like some copper alloys:

But don't use them if your fuel is diesel:

I can live with that. It's nice to know what the rules are. I think I'll get a copy of H-24 just to be safe.

JD |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 12

Registered: 08-2009

| | Posted on Thursday, August 20, 2009 - 09:26 pm: |

|

I just found a 1978 copy of Ian Nicholson's Boat Data Book in my collection. It says that Petrol engines consume 0.6 pints of fuel per BHP-hr. So, at 2 hp, for 8 hours, I would consume:

( 0.6 pints / (HP-hr) ) * 8 hr * 2 hp / (8 pts / gal) = 1.2 gallons of fuel.

Looks like I don't need a very big tank.

JD |

kerrigan

Member

Username: kerrigan

Post Number: 18

Registered: 06-2008

| | Posted on Thursday, August 20, 2009 - 10:18 pm: |

|

That is correct. A small tank will do. The fuel consumption is based on the horsepower consumed not the engines rated horsepower. |

ernie

Senior Member

Username: ernie

Post Number: 1017

Registered: 01-2002

| | Posted on Friday, August 21, 2009 - 07:14 am: |

|

My 20 ft fantail launch for the second year in a row used 1 gallon of fuel running all day at the Mystic show. In all reality all day was most likely about 5 or 6 hours. It has a 3hp Gray 2 stroke which is no where as stingy on gas as a YT1. It has a 3 gallon tank. |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 13

Registered: 08-2009

| | Posted on Friday, August 21, 2009 - 09:09 am: |

|

Thanks, Ernie. That helps a lot. I didn't expect that the YT-1 would be all that efficient.

JD |

miro

Senior Member

Username: miro

Post Number: 388

Registered: 11-2001

| | Posted on Monday, August 24, 2009 - 09:59 am: |

|

The idea of making a custom fitted pan to collect the oily drippings is a good one - many DispPro owners have them because they'd like to contain the messy oily stuff and prevent it from spreading al over the inside of the hull.

Purists however, stick to the notion that the smell of an oily bilge ( along with some old mouse droppings left over from last year) simply adds the experience of boating in an old wooden boat with an old marine engine.

And yes, some of them evenmop up the mess from time to time.

IN the past 15 years, I've only lifted the floor boards once. It was a gooey heap of black oily muck - haven't done it recently - maybe this year?

I rationalize that it helps preserve the boat and past traditions.

miro |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 14

Registered: 08-2009

| | Posted on Monday, August 24, 2009 - 10:24 am: |

|

Thanks, Miro.

Speaking of what's under the floorboards and all, I have really been struggling in my head about how to refinish the interior of the hull. It had been varnished and of course that finish was a mess. So I stripped it all with chemical stripper (I would have preferred to use heat and a scraper like I did on the exterior, but I gave up on that idea in the face of the complexity of the ribs and the lapped strakes.) What a lot of work that was. In the process I vowed to find a different way to finish the interior that would not flake like varnish and that I could just clean then re-coat once a season. I figure I will remove the floor boards (more like strips) regularly to maintain the varnish on them, thus exposing the ribs and strakes for re-coating. The boat builder in Maine (that recommended I seal the planking with 3M 5200) told me to just mop the interior with Penetrol. I've been considering other oiling options but worry that they require re-coating too often. I've considered the "Down East" blend that Jamestown Distributors mentions on their Varnish page (Pine Tar, Turpentine, Linseed Oil and Japan Dryer). I saw a couple of open boats like mine at a marine museum on Cape Hatteras that were finished with a similar formulation that looked great. But they were in a museum, not on the water and in the weather so who knows if it worked? So I have no confidence that any of these options will produce the desired results. Does anybody here have any suggestions/experience in this regard? Should I just buck up and varnish it and keep after it, knowing that I will probably have to go though that complete stripping process all over again 5-10 years down the line? I am not trying to create a museum piece here, but I am willing to take the time to at least do it somewhat right.

Thanks.

JD |

frank_petran

Senior Member

Username: frank_petran

Post Number: 61

Registered: 05-2009

| | Posted on Monday, August 24, 2009 - 11:52 am: |

|

If you spen all that time and energy cleaning the bilge ther is a product called Smiths Clear Expoy Sealer. It is a natural Epoxy sealer for wood. As I and a host of boat restorers use it for sealing everything below the water line both inside and outside. One of the premier boat restorers in the country, Danenberg, uses it also.

Google Smith Clear Epoxy penetrating sealer. You can coat it several times and it will still look almost clear. You shouldn't have to refinish it for several years (10 to 15)

Frank |

doug11k

Senior Member

Username: doug11k

Post Number: 66

Registered: 12-2003

| | Posted on Tuesday, August 25, 2009 - 08:38 am: |

|

I would use the copper tank but seal it inside with two part epoxy Kwik-Poly or as a second choice Red-Kote. Search Google for source. Have seen old style gasoline in uncoated copper tanks turn a bright John Deere green. |

jdheinzmann

Member

Username: jdheinzmann

Post Number: 15

Registered: 08-2009

| | Posted on Tuesday, August 25, 2009 - 09:24 am: |

|

Yikes, if that happens inside the tank, what happens inside the copper fuel line (that the coast guard specifies)? What do you think is going on? Does the tank turn green because the fuel cleans away all the oils making it easier for oxygen to get at the surface of the copper and oxidize it?

Thanks.

JD |

ernie

Senior Member

Username: ernie

Post Number: 1019

Registered: 01-2002

| | Posted on Tuesday, August 25, 2009 - 04:45 pm: |

|

there is no air in the line (hopefully) |