| Author |

Message |

narrabay

Member

Username: narrabay

Post Number: 20

Registered: 02-2016

| | Posted on Sunday, March 06, 2016 - 10:09 pm: |

|

After more endless interwebs, I dicovered the Dispro boat/drive products and thought "how cool". In fact I have a couple key questions because I cant find close-ups (yet) of the underside parts like u-joint.

My question really is though, can these be driven in reverse? I dont see any with a reverse gear and wondered if maybe the u-joint scheme cant accommodate reverse thrust?

Speaking of which, where is the thrust delivered, through that u joint, or before it such as at the strut? Any info appreciated, I'm kind of new to this fascinating and fun world. |

ernie

Senior Member

Username: ernie

Post Number: 2232

Registered: 01-2002

| | Posted on Monday, March 07, 2016 - 02:33 pm: |

|

Most Dippys are 2 strokes and just run backwards.

You should see Miro when he gets caught up in the device... |

narrabay

Member

Username: narrabay

Post Number: 21

Registered: 02-2016

| | Posted on Monday, March 07, 2016 - 02:53 pm: |

|

hi ernie, thanks. so from your reply it looks like there is nothing about the dispro drive system that would preclude running a reverse gear 4 stroke mill and using reverse? in other words, the u-joint doesnt pull apart! ;)

that is good news  |

bruce

Senior Member

Username: bruce

Post Number: 532

Registered: 07-2002

| | Posted on Monday, March 07, 2016 - 03:07 pm: |

|

Orphan Dispro devices are more scarce than Donald Trump fans in Boston.. |

narrabay

Member

Username: narrabay

Post Number: 22

Registered: 02-2016

| | Posted on Monday, March 07, 2016 - 07:33 pm: |

|

Bruce thanks but lets not get politics into the boat topic. Then again, if I had a Dispro unit or whole boat to enjoy, America *would* be great again no matter who is president! lol |

worth

Member

Username: worth

Post Number: 7

Registered: 12-2011

| | Posted on Monday, March 07, 2016 - 08:35 pm: |

|

Narrabay, if you would like to see a really nice Dispro, in a really nice boat, make a trip to the Glenn Curtiss Museum in Hammondsport, NY. But you might as well wait until summer and visit some of the Finger Lake wineries while you"re at it! |

narrabay

Member

Username: narrabay

Post Number: 23

Registered: 02-2016

| | Posted on Monday, March 07, 2016 - 10:58 pm: |

|

I'll add that to our weekender ideas list, thanks! |

miro

Senior Member

Username: miro

Post Number: 848

Registered: 11-2001

| | Posted on Tuesday, March 08, 2016 - 07:58 am: |

|

As a production version, the DisPro did not have a reverse.

The flexible joint is(present tense)manufactured by Gray and Prior of Connecticut and are still in business and can still provide replacement joints.

Generally, the boats are so slow that there's no need to reverse. And getting away from a dock or a boathouse is done with paddles.

Unlike the bateaux of Louisiana, these boats are much more leisurely when coming into a dock.

The other issue is how to steer the boat if it were reversing - the rudder is way at the back, and would be practically useless.

However, there were special one-of-a-kind versions made with small 4 cylinder engines with integrated FNR transmissions - but they were mainly built because the owners wanted electric start engines.

In the DisPros built after about 1923-1924, you wouldn't want to run the engine in reverse anyway because there is a very high likely hood that the recoil start mechanism would catch and it would be destroyed.

If on the rare occasions that my engine does start, cough and run backwards, I immediately shut it down.

SO , no reverse - not needed - plan your moves in ( not much) advance.

Miro |

miro

Senior Member

Username: miro

Post Number: 849

Registered: 11-2001

| | Posted on Tuesday, March 08, 2016 - 08:03 am: |

|

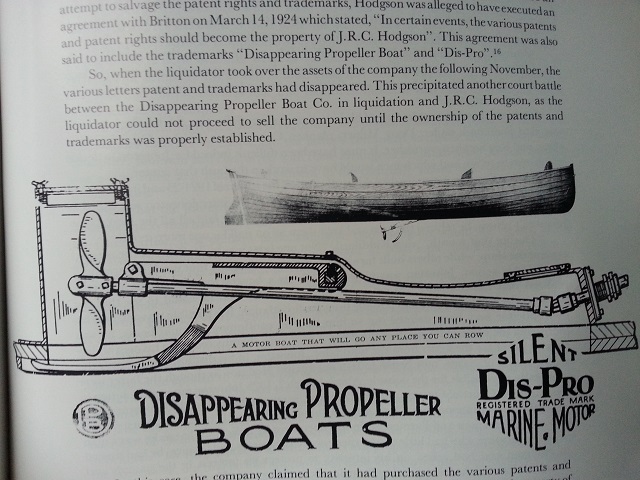

Here's a drawing in cross section of the device

http://www.dippy.ca/adpics/ad2.htm

Miro |

narrabay

Member

Username: narrabay

Post Number: 24

Registered: 02-2016

| | Posted on Tuesday, March 08, 2016 - 01:42 pm: |

|

Thanks Miro for that good solid information, I'd like to see that u-joint, it is the key component. any contact info for that outfit? Also, do you or anyone have a clear pictures of that part? Does it have a waterproof boot, or other way to resist corrosion such as being stainless?

thank you |

miro

Senior Member

Username: miro

Post Number: 850

Registered: 11-2001

| | Posted on Tuesday, March 08, 2016 - 10:55 pm: |

|

Well it would appear that last fall Gray and Prior closed its operations.

http://www.auctionguy.com/gray-prior-machine-co-s-283334.html

I tried searching for their web site, to no avail.

The joints are not protected from the water. and are quite small. They did make stainless joints.

I'll take some pictures tomorrow.

Not good news

Miro |

miro

Senior Member

Username: miro

Post Number: 851

Registered: 11-2001

| | Posted on Wednesday, March 09, 2016 - 10:37 am: |

|

Here's a picture of a version of the joint

On the DisPro, though, there is a bore on either end

instead of a square drive.

Miro

|

bruce

Senior Member

Username: bruce

Post Number: 533

Registered: 07-2002

| | Posted on Wednesday, March 09, 2016 - 10:12 pm: |

|

Looks like something you could get from the Snap-On tool vendor .... |

narrabay

Member

Username: narrabay

Post Number: 25

Registered: 02-2016

| | Posted on Wednesday, March 09, 2016 - 10:27 pm: |

|

I think I will need to ask on dispro sites for the close up. while I dont plant to try this on my current project, I really do want to learn how dispro works for future reference. and it is a really need idea. |

narrabay

Member

Username: narrabay

Post Number: 26

Registered: 02-2016

| | Posted on Friday, March 11, 2016 - 03:11 am: |

|

funnily, I cannot seem to find any pictures of the actual dispro u joint or mechanism underneath so far. anyone have that, and pics of the underside? I did find a video of servicing the mechanism, but doesnt show the shaft and u joint. is the u joint stainless? or does it have a boot for protection? how well do they hold up I wonder? |

bruce

Senior Member

Username: bruce

Post Number: 534

Registered: 07-2002

| | Posted on Friday, March 11, 2016 - 10:00 am: |

|

Chris, Study/read disproboats.ca and dippy.ca via Google. |

bruce

Senior Member

Username: bruce

Post Number: 535

Registered: 07-2002

| | Posted on Friday, March 11, 2016 - 10:31 am: |

|

Chris, There is a 13 episode U-tube video series on "installing an inboard motor in a homemade wooden boat" The engine is a 4 cycle Kermath Sea Pup. |

narrabay

Member

Username: narrabay

Post Number: 27

Registered: 02-2016

| | Posted on Friday, March 11, 2016 - 01:10 pm: |

|

Hi Bruce, thank you. I had actually saved that series in my "inboard dinghy" project shortcuts. But it looks to me (see episode 6) like an Atomic 4, and the Sea Pup is a single cylinder. As to the 2 sites, those are also in my faves, and I saved the maintenance PDF docs as well. But never found a clear shot of the underside and universal joint.

While I may have missed

I posted this thread to learn specifically about the Dispro universal joint type and whether it can tolerate reverse. I also am pretty sure - but not 100% - that thrust is exerted on that u joint and not, for example, at the strut. So it *looks like* the u-joint can handle thrust forward and backwards.

It would be also good to know if that u-joint is stainless, has a watertight rubber boot, or how it resists corrosion and how it is lubricated.

This curiosity is for learning and I will have my hands full just getting a basic engine and trans and running gear into my Dory this year.  |

narrabay

Member

Username: narrabay

Post Number: 30

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 12:24 am: |

|

So... no one here has a picture of an actual Dispro u-joint?

Miro, that picture you posted, what is that silver thing actually from?

Again, I'd like to know if the dispro u joint is stainless, and / or has a boot, etc. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 46

Registered: 03-2013

| | Posted on Sunday, March 13, 2016 - 03:21 am: |

|

The picture that Miro posted is a universal joint.

Maybe you need to take a look at other craft that employ a prop/shaft that retract into a case. Flat bottom dories would be a start.

If your going to fab this then you should answer alot of the questions re material- lubrication etc for yourself...... by sitting down for an hour with a copy of

Marks' Standard Handbook for Mechanical Engineers

All will be revealed.

Got any pics of your dory? |

narrabay

Advanced Member

Username: narrabay

Post Number: 31

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 03:57 am: |

|

Is Miro's pic an actual Dispro U Joint and when installed does it have a rubber boot to keep the water out? Thanks

Also, still looking for some actual pics of actual Dispro u-joint installed in the boat. Is that a national secret? LOL |

miro

Senior Member

Username: miro

Post Number: 852

Registered: 11-2001

| | Posted on Sunday, March 13, 2016 - 08:50 am: |

|

Guys, the u joint is nothing special.

It can be stainless, but most of the boats I know use a steel one. Yes, they are subject to corrosion, but most of them last at least 20 years - in fresh water.

DisPros should really never be run in salt water because of the galvanic corrosion due to dis-similar metals.

There is no boot covering them. They do not require lubrication.

The joint can be run in reverse.

The whole arrangement is based on very low HP.

The nominal HP of the engines are about 3 - 4 , but actual HP at the propeller is about 1/2 HP, based on testing on my boat that I did last year.

The secret of the whole thing is not the u joint, but it's the skeg, cutlass bearing support, and lever arrangement, that allows the back part of the shaft to be swung up into the housing while the whole thing is running - the so-called "Device". The skeg, bearing and lever is shown quite clearly in the diagrams.

I'll see what I can do about getting a picture of a used joint and shaft. A picture of the skeg, cutlass bearing and lever is another matter altogether - you'd have to take the whole thing apart. I know of no DisPro owner that is interested or would allow that.

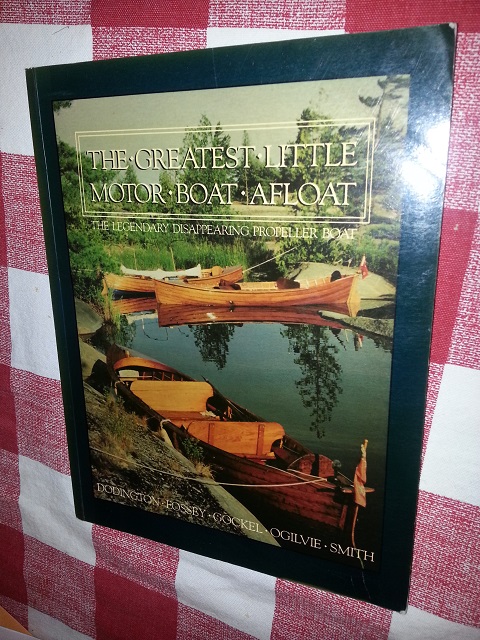

You might try getting the book - The Greatest little motor boat afloat"

Miro |

narrabay

Advanced Member

Username: narrabay

Post Number: 32

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 12:12 pm: |

|

miro thanks. I did look at that book on amazon, and may order it. I'm asking so as to understand the dispro, but not looking to own one (maybe someday). hoping to install a regular slow RPM inboard into my existing 12ft hull. we live on a salt water bay so thats another consideration. I wonder if there is a running Dispro here in the NorthEast, would drive 150 miles to go see one... |

miro

Senior Member

Username: miro

Post Number: 853

Registered: 11-2001

| | Posted on Sunday, March 13, 2016 - 12:33 pm: |

|

Hi Chris,

Here are some pictures of hte shaft and joint as promised.

Salt water ain't good for these boats - actually it's pretty evil - so many dis-similar metals.

I know of one owner who was visiting Georgia and ventured out in brackish water for maybe 15- 20 minutes of running and when he came back spent the next afternoon flushing the salt-ish water out of everything.

I'll have a look at the Club directory to see if there is one near you - I don't recall one, though.

Miro

Most of the time when running, the shaft is straight so the joint isn't being stressed.

When coming into dock,I usually slow the engine to about 250 RPM so again the joint is not being stressed too much.

|

narrabay

Advanced Member

Username: narrabay

Post Number: 33

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 01:46 pm: |

|

Thanks! Is that really an iron or steel prop shaft? That joint, does the pin rock in the hole, because I dont see how it can bend in the other axis. Looks like no bearings either. Interesting. And easy to replicate in stainless with a stainless shaft.

Btw, when I make my boat, no salt water will ever get to the engine. Will use keel cooler with antifreeze protective coolant. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 47

Registered: 03-2013

| | Posted on Sunday, March 13, 2016 - 03:00 pm: |

|

Easy? You must have a dumpster of scrap 316 SS available for free and a decent size lathe in your shop!

Seriously get the books mentioned above and spend an hour or two reading, it will really help focus your questions. Books, Books, Books.

So what 12 foot hull are you building? Neat to see some pics of it. 12 feet is tight for an engine-transmission- shaft case interested to see how it is arranged. |

narrabay

Advanced Member

Username: narrabay

Post Number: 34

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 03:35 pm: |

|

Hi dave, I actually have a hand-laid fiberglass dory with a lapstrake design. Its pretty old school looking. Hoping to drop a 1 cyl into it. Im working now but my other thread has a picture. Eventually, I have a hull in mind thats 14ft which is really traditional looking, whereas mine is passably old looking. I dont have a lathe or stainless or skill, but I think I know someone who can make a u joint. But not looking to do that at first, maybe later. There obviously is more to it than the u joint but that was the part I understood the least.

What would be nice someday would to build a wooden hull of the exact ideal design, upswept at the back for a more level prop shaft, a keel, vertical stem, lots of freeboard, and traditional curves, and use it as a mold. But that probably a pipe dream or way in the future.

Right now its about a reliable 1cyl into my current hull with a normal log, shaft, etc.

These questions about the dispro are out of abject curiosity and maybe for future reference. The Dispro is just so cool! |

narrabay

Advanced Member

Username: narrabay

Post Number: 35

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 04:08 pm: |

|

|

miro

Senior Member

Username: miro

Post Number: 854

Registered: 11-2001

| | Posted on Sunday, March 13, 2016 - 04:44 pm: |

|

The u joint pins are mounted on a square steel block, so they can move. Yup - steel, not iron.

That shaft was probably in service for about 30 years. In a pinch it probably could be re-installed successfully.

The shaft is supported by the shaft log inside the boat at the front end of the Device casting, and at the skeg, the cutlass bearing is supported by the arm that hangs below the boat. The shaft bearing is mounted on a hinged arrangement so it can accommodate the changing geometry as the shaft is pulled up into the Device housing. The cutlass bearing slides to and fro on the prop shaft as the geometry changes.Quite clever actually - I understand your fascination.

As for your design, I'd be a bit cautious about too much freeboard. In a stiff wind, your boat will make almost no headway with only a small , low HP engine. This especially true if the wind is blowing from either quarter.And besides, I doubt that you'll be out in it, with wind and big waves.

You know that longer displacement hulls go faster for the same HP - a function of the square root of the hull length at the water line. I'd suggest a 14 ft length - it will make a difference for the small amount of additional material and effort

And just in case you are truly fascinated, there is a hull form available for an 18 ft DisPro that has been used by a number of amateur builders to make their own DisPro.

Miro |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 48

Registered: 03-2013

| | Posted on Sunday, March 13, 2016 - 05:02 pm: |

|

Fantastic little boat. With a seagull outboard you'd really have a smart craft! Hull speed and under twenty pounds of wieght........

Single cylinder, cast iron block, exposed flywheel, big 9 inch prop, salt water tolerant.

Or maybe an elto rudder twin.....Get you playing while you work on your inboard project. |

narrabay

Advanced Member

Username: narrabay

Post Number: 36

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 05:23 pm: |

|

Hi Dave I actually do have a seagull outboard that I just bought for $100 but it's a featherweight or Featherlite the smallest one they made I planned on carrying it has a spare in my inboard in case the inboard engine had any trouble while I was on the Water Somewhere. I have a few other topics that I started which will draw more complete picture of where I'm going with all this when I was a little kid I actually used to build inboard rowboats using an old cast iron Briggs & Stratton engine. The most satisfying versions were ones where I used the large left hand bronze propeller which loaded down the engine to less than 1000 rpms. one of the defining goals of my efforts in the Antique Boat and antique engine area is to recreate the experience of a very slow turning engine I think it's very relaxing I will post a picture of the 1930s hull that I found which was being made in Canada until recently I'm not sure anymore I'm trying to find out. But my current boat will need the installation of stringers and obviously a shaft log and a strut and the related running gear in order to install a small inboard so I won't be able to play with it using the seagull outboard while I'm working on the project (unless I get a really big bilge pump). I am glad you like the hull. Eventually I hope to have a completed project that is indistinguishable from a boat from the era (other than fiberglass contruction) and hoping any subsequent project to maybe build a wooden Hull I have already looked at online videos and check into courses that I can take toward that end, that is the only way to get something that is genuinely antique in materials and workmanship and exactly the size and shape and design that I might have in mind later. Here is what I think a great hull. |

david_doyle

Advanced Member

Username: david_doyle

Post Number: 49

Registered: 03-2013

| | Posted on Sunday, March 13, 2016 - 06:27 pm: |

|

An Elto rudder twin running on a battery will give you the low and slow you are looking for and preserve the fiberglass hull. Well laid up glass hulls are tomorrows desirable antique. Just my bias but I live by the adage to never drill a hole in a boat once construction is complete. Of course my boats are usually glass over wood so I am paranoid.

That feather wieght gear box is desirable to the seagull racing crowd in the UK- Auz- N.Z- Bermuda. Probabley find someone willing to swap for a regular gear box, I think the rest is the same. If you have a Villiers magneto get them to throw in a complete wipac ignition system. The villiers will let you down guaranteed and replacement coils are big $ or non obtanium.

cheers |

bruce

Senior Member

Username: bruce

Post Number: 538

Registered: 07-2002

| | Posted on Sunday, March 13, 2016 - 08:41 pm: |

|

Chris, Take a drive to Kingston RI and check out the fiber-glas hulls Walt Beckmann is building at his Beckmann Boatshop Ltd. shop. These are circa 1910 Truscott fan tail launches made in Fiber-Glass. Classic traditional launch close to home and ready to finish off and fit up with classic power of your choice. 300 Bridge Road, North Kingston RI Walt can answer all your questions.. |

bruce

Senior Member

Username: bruce

Post Number: 539

Registered: 07-2002

| | Posted on Sunday, March 13, 2016 - 08:48 pm: |

|

Chris, Update on Beckman Boatshop address: 500 Indian Corner Road, Slocum RI. Phone 401-294-1030 |

narrabay

Advanced Member

Username: narrabay

Post Number: 37

Registered: 02-2016

| | Posted on Sunday, March 13, 2016 - 08:49 pm: |

|

Bruce thats awesome, right in my backyard. I will check that out.. |

bruce

Senior Member

Username: bruce

Post Number: 540

Registered: 07-2002

| | Posted on Sunday, March 13, 2016 - 09:06 pm: |

|

Chris, Update on Beckman Boatshop address: 500 Indian Corner Road, Slocum RI. Phone 401-294-1030 |

G. Roehl Sr.

Visitor

| | Posted on Monday, March 14, 2016 - 08:47 pm: |

|

Gentlemen (and the occasional lady).... I have forgotten my login, so yous gets me real name (not that it mattered). I've been an interested "lurker" for years now. The u-joint shown above is a basic pin and block (the simplest form). While you could have one made up, they are also available off-the-shelf through suppliers like McMaster-Carr. A bit pricy, but available in steel and 303SS. Reference catalog 121 (the current edition) pg. 1219 or on-line: http://www.mcmaster.com/#universal-joints/=11jijqy |

G. Roehl Sr.

Visitor

| | Posted on Monday, March 14, 2016 - 08:49 pm: |

|

Gentlemen (and the occasional lady).... I have forgotten my login, so yous gets me real name (not that it mattered). I've been an interested "lurker" for years now. The u-joint shown above is a basic pin and block (the simplest form). While you could have one made up, they are also available off-the-shelf through suppliers like McMaster-Carr. A bit pricy, but available in steel and 303SS. Reference catalog 121 (the current edition) pg. 1219 or on-line: http://www.mcmaster.com/#universal-joints/=11jijqy |

G. Roehl Sr.

Visitor

| | Posted on Monday, March 14, 2016 - 08:52 pm: |

|

Apologies for the double post. I got a timed-out response.... |

narrabay

Advanced Member

Username: narrabay

Post Number: 38

Registered: 02-2016

| | Posted on Monday, March 14, 2016 - 11:01 pm: |

|

That's great!!! IF I decided to add Dispro-like ability to a boat, that part would be key. I'd probably get the stainless version, and use a rubber boot filled with grease around it. For a real hot ticket, using two, one inside the boat to level the engine would really be cool. Some of them mention a 300 RPM speed, I'm sure there is some margin on top of that (one would hope) and of course as Miro I think pointed out, at least a traditional Dispro (without my "engine leveling option") would be running the joint straight most of the time and there would be no "working" it when running. |

bruce

Senior Member

Username: bruce

Post Number: 541

Registered: 07-2002

| | Posted on Tuesday, March 15, 2016 - 09:21 am: |

|

My 1921 Gilbert skiff-putt ( built briefly in New Jersey )uses a sail boat like trunk that a-butts to the transom so that the trunk creates a 3 inch wide vertical slot in the face of the transom. The drive shaft attached to the engine drives level through the forward vertical face of the sail boat-like trunk via a water tight gland fitting. A universal joint and prop shaft riding in the water with-in the trunk is carried in a prop strut which is supported by a vertical post which can slide up and down in two heavy pintal fittings. The top pintal has a threaded clamp handle which binds the vertical post and attached strut at the desired prop depth. The slot in the transom allows the prop and shaft which extends beyond the transom to be raised clear of the bottom of the boat. I'm told this arrangement is common in the Canadian Maritimes for beaching small powered fishing boats and may be called a (?)Tuck-Up.Kind of a poor mans Dispro... |

herbertchoover

Member

Username: herbertchoover

Post Number: 8

Registered: 04-2016

| | Posted on Tuesday, May 03, 2016 - 12:35 am: |

|

bought the book, it arrived today. GREAT book I highly recommend, lots of history and the detail on the dispro...

|