| Author |

Message |

charliea

New member

Username: charliea

Post Number: 2

Registered: 06-2010

| | Posted on Saturday, November 06, 2010 - 06:58 pm: |

|

I have a 1 cyl 2 cycle palmer Q1 26901C Do not know hp or year. Would like to find a rebuild shop manual and another cylinder, carb, ingition set up.

Charlie a |

richardday

Senior Member

Username: richardday

Post Number: 909

Registered: 11-2003

| | Posted on Saturday, November 06, 2010 - 08:27 pm: |

|

Charlie, The serial number is interesting. I have a couple of dozen Q serial numbers and yours is the only early Palmer serial number ending with a letter. If it were a zero as in 269010 it would make more sense. 10 would indicate made in 1910. Can you tell me if the water pump mounting on the aft face of the cylinder has a two bolt or three bolt mounting flange? About 1916 Palmer changed from the two bolt to three bolt flange. The HSP is 3 at 700 RPM. Why do you need a new cylinder?? They are nearly impossible to find. If you could put a photo or two on the page we might be able to guide to someone who could restore your cylinder. Andrew sells a reprint of the Palmer handbook which is probably the best single volume covering these antiques and much of it relates to any of the two and four strokes of the period. Any chance we can see a picture of the serial number tag as well as the engine?? |

charliea

Member

Username: charliea

Post Number: 4

Registered: 06-2010

| | Posted on Sunday, November 07, 2010 - 09:04 am: |

|

So much for the serial # you were right last # was a zero not a C Here are some phtos of poor quality. the water jacket has many leaks the owner said it was from salt water use. I also have a short / long block that I could xfer all the parts to

. I would much rather have two motors than one. I suspect the parts I want would cost more than I paid for both motors. What is the real value of a motor like this. I bought it to put in a boat not collect?

Thanks charlie a

|

john_archibald

Senior Member

Username: john_archibald

Post Number: 153

Registered: 08-2006

| | Posted on Sunday, November 07, 2010 - 09:41 am: |

|

Has anyone ever just cut off the water jacket completely on an engine like this leaving a ring ( land ) at the top and bottom so that a sleeve can be slipped over these lands? O-rings in the lands or in the sleeve would seal things.

Rarely, I would guess, is the cylinder wall ever cracked. If these engines develop cracks, it is probably from water left in the jacket which freezes in the cold months. This would create a tensile stress in the outside wall of the water jacket and a compressive stress in the cylinder wall itself.

That's why the cylinder walls are hardly ever cracked. Cast iron is very strong in compression. Not so in tension, which leads to the outside wall of the water jacket failing.

A large boring mill ( vertical lathe ) or a large engine lathe would probably be the tool of choice to make this kind of repair. I would be inclined to try it for a very far gone engine in otherwise good shape.

Archibald

Northfield, Minnesota |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2471

Registered: 11-2001

| | Posted on Sunday, November 07, 2010 - 10:09 am: |

|

*

* |

john_archibald

Senior Member

Username: john_archibald

Post Number: 154

Registered: 08-2006

| | Posted on Sunday, November 07, 2010 - 10:30 am: |

|

Yes, that's the idea, but do it as an engine rescue tool. Fit O-rings in the lands and slip the sleeves over the cylinders. There won't be any axial forces, except weight, and they won't leak a drop. Also, with my scheme they could be removed to clean the outside cylinder wall. That's an advantage.

Thanks for posting such explicit photos.

Archibald

Northfield, Minnesota |

robert

Senior Member

Username: robert

Post Number: 391

Registered: 07-2003

| | Posted on Sunday, November 07, 2010 - 01:44 pm: |

|

Your engine is very repairable. Suggest you study this thread first: http://www.oldmarineengine.com/discus/messages/1/91556.html |

richardday

Senior Member

Username: richardday

Post Number: 910

Registered: 11-2003

| | Posted on Monday, November 08, 2010 - 05:54 am: |

|

Charliea, Glad we sorted out the serial number problem. Now you have a very restoraable Q-1 made in 1910 with a 5 spoke flywheel, most Qs seem to have six. Don't try to cut the cylinder up and put in a sleeve etc. before you ask George Coates in Elkton, MD. for help.

410-620-0215

Those folks are geniuses at recovering seriously damage cylinders. They have a cooking process which removes any salt if salt in the iron caused the cracks. In any case they can make that cylinder like new. Their charges as I know them are very reasonable.

Your Q-1 has an interesting base in that you can see the boss on the "PORT" side for the two port check valve which was the first version of the Q-1. I have a simalar base Q-1 the boss like yours not machined. That boss disapears in later year production. It looks like you have a Palmer made timer. Some years later Palmer starting using Cuno timer. Two bolt water pump is correct for early production Q engines sometime around 1916 I guess they switched to a three bolt pump flange. Probably due to water leaks developing at the flange due to the thrust of the pump plunger. My advice is don't separate the upper and lower portion of the crankcase if you can avoid it. Getting the right clearances for the crankcase gaskets is a tricky business and critical to proper operation. If there is no slop in the crankshaft bearins leave well enough alone clean out all the old grease in the grease cups and piping and use old time water pump grease. In operation about 1/2 turn of each grease up every 20 to 30 mins. Hey running one of these engines in 1910 was not a walk in the park. Ernie says 16 to 1 oil to gasoline mix. I say SAE 30 non detergent 40:1 was the old time mix. Take your pick just don't run without oil in the fuel!!!! Good luck. |

speleausmining

Member

Username: speleausmining

Post Number: 11

Registered: 10-2010

| | Posted on Tuesday, November 09, 2010 - 09:14 pm: |

|

Theres no reason one could not do that with a water jacket. though I would be inclided to weld or braze the seam. I can certainly see the advantage of a removable water jacket for engines used in salt water where corrosion is a factor. Has anyone tried placeing sacrifical anodes in an engine water jacket? I am thinking specifically of Zinc plugs in unused jacket ports which would extend a short ways into the water jacket. Seems to me this would at the worst do no harm and may help prevent corrosion to the cast iron. though again its mainly a problem of salt water. Corosion can also cause a jacket to "pop" Metal expands with terrific force as it rusts and particularly if there is deposits of some type taking up space in the jacket this can cause it to pop. Salt water enviroments are pretty rough on equipment so its a testament to the durability of these engines that so many still survive. |

robert

Senior Member

Username: robert

Post Number: 393

Registered: 07-2003

| | Posted on Tuesday, November 09, 2010 - 09:32 pm: |

|

I've seen iron hollow cast 1 inch pipe plugs filled with zinc. When screwed into the holes in the water jacket where the core sand was removed, they were supposed to help reduce corrosion. Don't know if they did or not! |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2472

Registered: 11-2001

| | Posted on Tuesday, November 09, 2010 - 11:52 pm: |

|

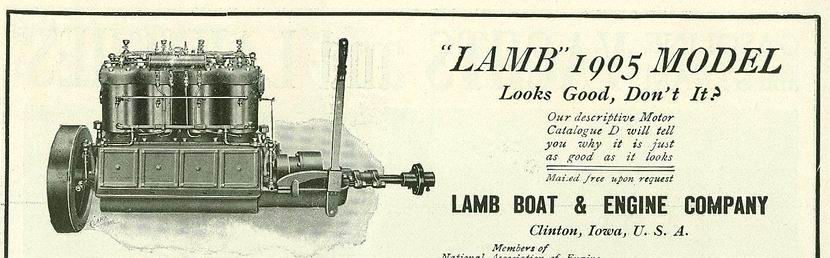

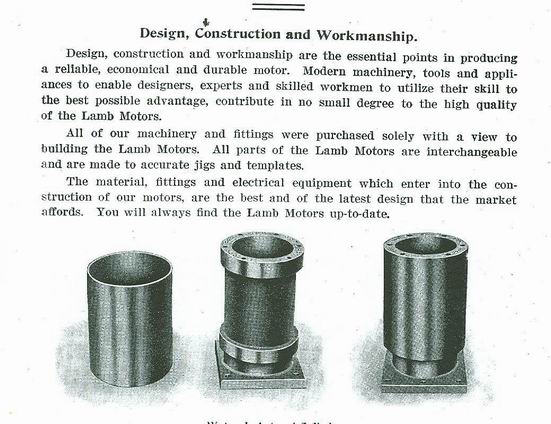

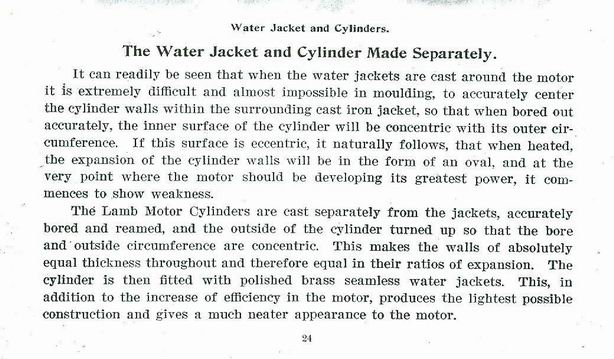

*

Posting the Lamb 1905 ad and the construction of their cylinders with sleeves is a great way to mfgr a marine engine but I would not recomend doing that to your Palmer Q, I have repaired worse than yours by grinding grooves in the cracks and end drilling them I then heat cyl in an old barbecue grill put them in a box of sand on the bench and braze the cracks with rod and acetylene torch, done many with no problems, but when finished I keep the cyl full of antifreeze and an additive chemical called sta-clean that I have used in cooling systems for 30 yrs !

The Zinc anode plugs mentioned are a common item in marine engines,I have changed hundreds of them on all types of gas and diesel marine engines as a standard service procedure, they are for protection of components of engines from electrolytic corrosion- or electrical currents in the cooling chemical that disolves metals, the Zinc anodes are low on the galvanic scale and are the sacraficial metal in the system but as they dissolve replacement is necessary or engine metal will then become the sacraficial metal.

The cracks in these old Marine engines are in most cases the result of salt water cooling and the expansion and crystalizing of the salts that have penetrated the actual cast iron, a very different type of corrosion than electrolytic !!

There was a lot of discussion on this subject here several yrs back you might go to the search and look around for those old posts.

* |

richardday

Senior Member

Username: richardday

Post Number: 913

Registered: 11-2003

| | Posted on Wednesday, November 10, 2010 - 11:03 am: |

|

I have a big Lathrop two cylinder two stroke which has large rectangular zincs inside rectangular about 2"X 3" ports in the lower portion of each water jacket. |