| Author |

Message |

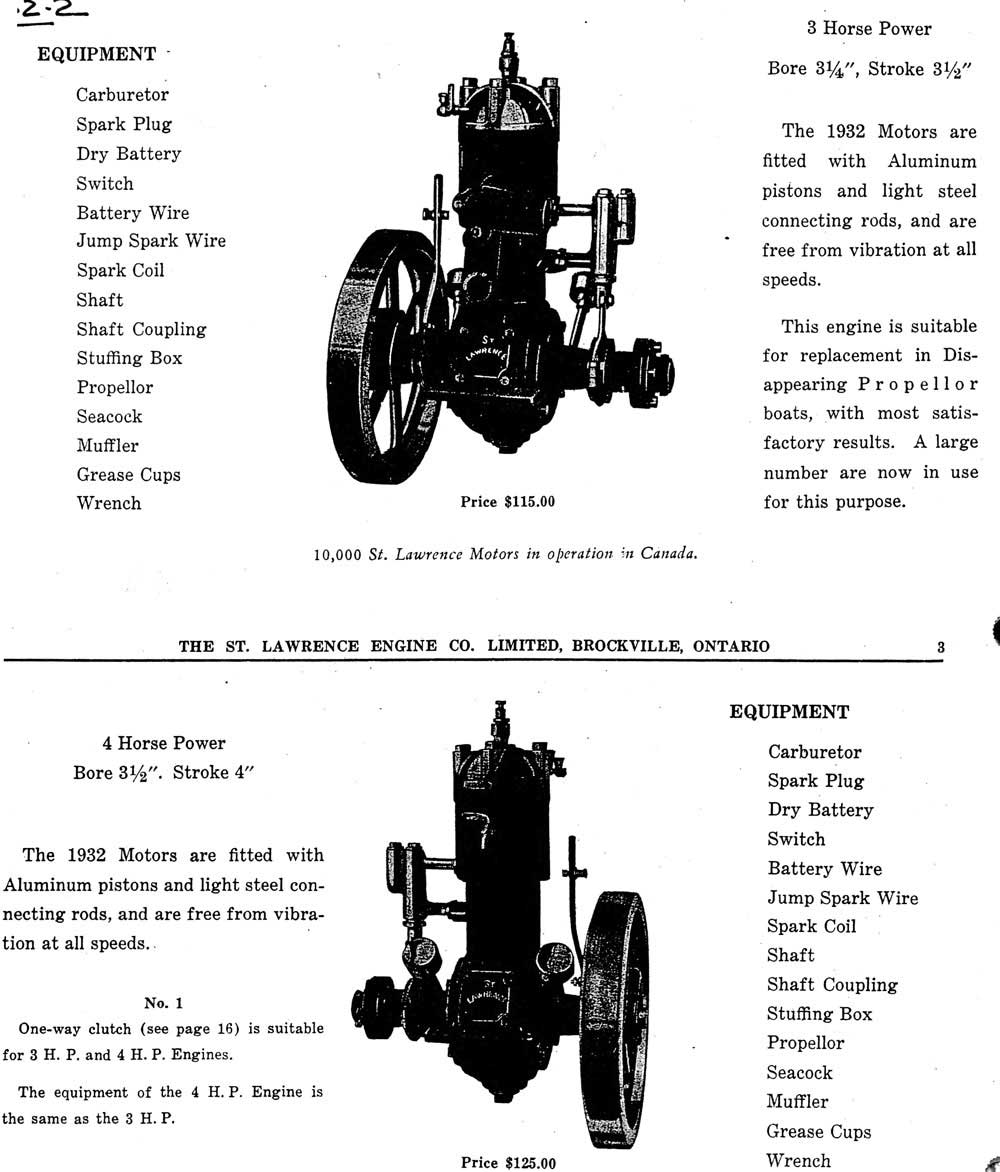

chris_spring

Senior Member

Username: chris_spring

Post Number: 90

Registered: 02-2019

| | Posted on Tuesday, December 29, 2020 - 04:03 pm: |

|

What do you guys make of this? At that price point, is it worth investigating? what are the pitfalls?

Cheers!

https://www.facebook.com/marketplace/item/210677277331170/?ref=search&referral_c ode=undefined |

miro

Senior Member

Username: miro

Post Number: 1110

Registered: 11-2001

| | Posted on Friday, January 01, 2021 - 06:11 pm: |

|

In its present condition, you'd be buying a project. Usually for the price they are asking you'd get a complete, running engine.

I sort of wonder about why the flywheel is missing.They're big and heavy and hard to lose. Maybe it was cracked when it was being removed from the crankshaft.

The St Lawrence engine is a common engine - lots are still in use in DisPro boats - so if you take the dive, you'll have help to get parts.

Richard D has the database for serial number and date of mgf.

miro |

chris_spring

Senior Member

Username: chris_spring

Post Number: 91

Registered: 02-2019

| | Posted on Saturday, January 02, 2021 - 08:30 am: |

|

Thanks Miro.

It wasn't only the missing flywheel that made me wonder, I have no way of knowing who re-built it? The wording says rebuilt but never run. That could easily read it won't run now that we messed with it.

I don't see a complete timer or a few other parts in the pics either.

Thanks for your estimate on approximate value. Based on that alone I think I'll take a pass.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 92

Registered: 02-2019

| | Posted on Saturday, January 09, 2021 - 03:31 pm: |

|

It would appear the ser# on it is 5610. I know little about these engines. I don't even know what hp this would be. Interesting that the carb is installed upside down. My guess is that nevermind the fact that he says it has been re-built, it would likely be best to tear it right down and start again.

If someone could tell me year and hp, I might consider putting in a low ball offer. In fact I'd even take advice on how much to offer.

Cheers! |

miro

Senior Member

Username: miro

Post Number: 1114

Registered: 11-2001

| | Posted on Sunday, January 10, 2021 - 11:31 am: |

|

Check out the serial number list here

http://www.oldmarineengine.com/discus/messages/1/424198.html

I think it's 3 HP rating although Barry (BCM) could verify that. For 200 you probably won't go wrong - but it will be a project |

bcm

Senior Member

Username: bcm

Post Number: 137

Registered: 11-2009

| | Posted on Sunday, January 10, 2021 - 12:59 pm: |

|

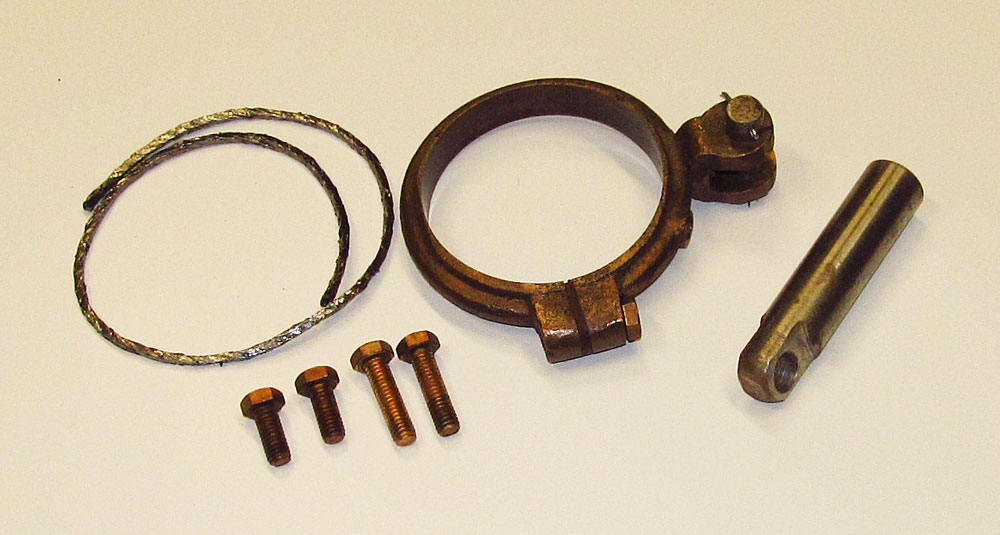

Chris,

It's either a 3HP or 4HP. Measure diameter of head. 3HP is 5 "diameter, 4HP is 5 1/2".

Looks like all parts plus extras are included except flywheel so you first need to find a flywheel. Also I don't see a shaft flange.

3HP is 12" diameter,4HP is 14". If 3 1/2" then if piston is cast iron, flywheel is heavier than engine with aluminium piston.

check this link http://www.oldmarineengine.com/discus/messages/5/1412.html.

Engine is probably late 1920s. Water pump eccentric and ball housings are from a 1940s engine. That's a plus.

Check condition of crankshaft and connecting rod bearing, also wrist pin, also cylinder condition and piston fit so that you know what may be required. The cd that you have SUBJECT 13 has useful info.

Barry

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 93

Registered: 02-2019

| | Posted on Sunday, January 10, 2021 - 01:27 pm: |

|

Thanks everyone. I first confirmed it was still available, then threw in the $200 offer Miro sugguested. No response. I'll let you know if I hear further.

My interests in this are several. First. I've always figured one can never own too many internal combustion engines. Second. I'd like to have a shot at making this run. Third. I'd like to ensure such a piece of Canadiana is not lost forever.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 117

Registered: 02-2019

| | Posted on Saturday, July 10, 2021 - 09:36 pm: |

|

It looks like there is some progress on this. I had to up my bid but I'm still well below the asking price. I'll see it first hand next week and take it from there.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 118

Registered: 02-2019

| | Posted on Friday, July 16, 2021 - 12:22 pm: |

|

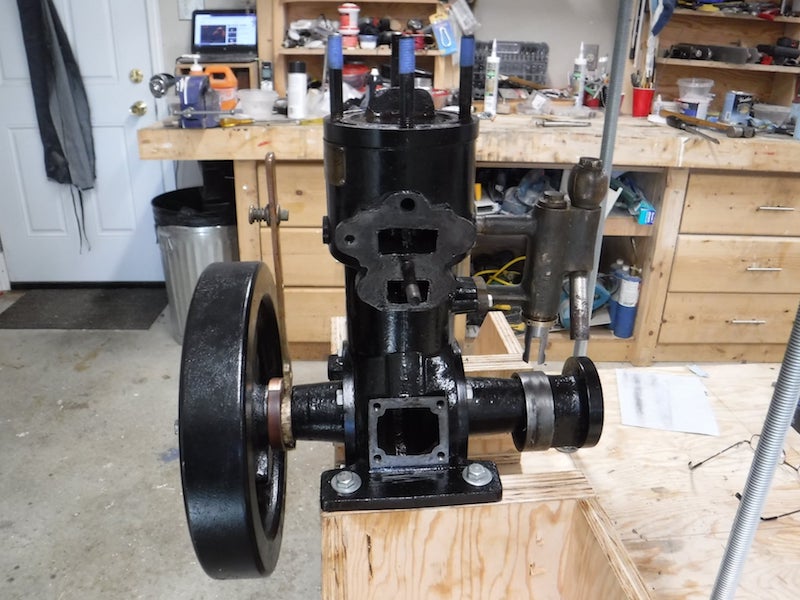

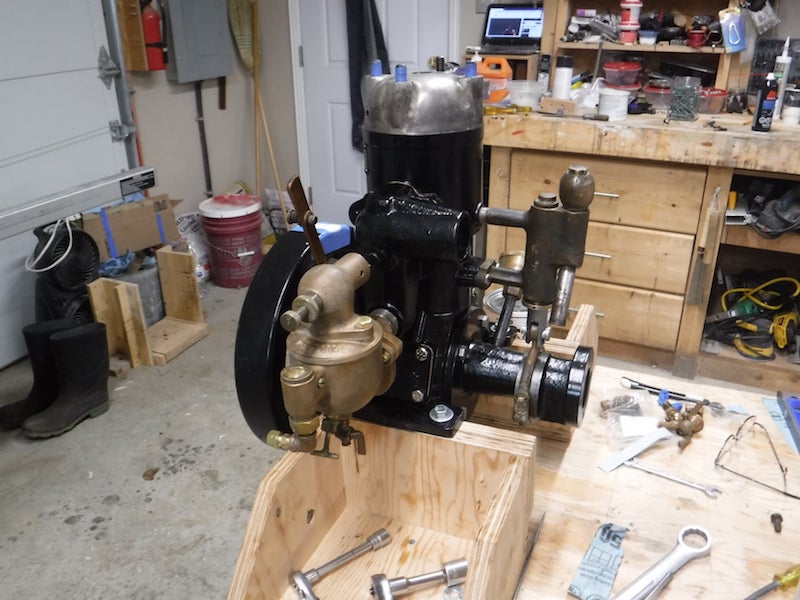

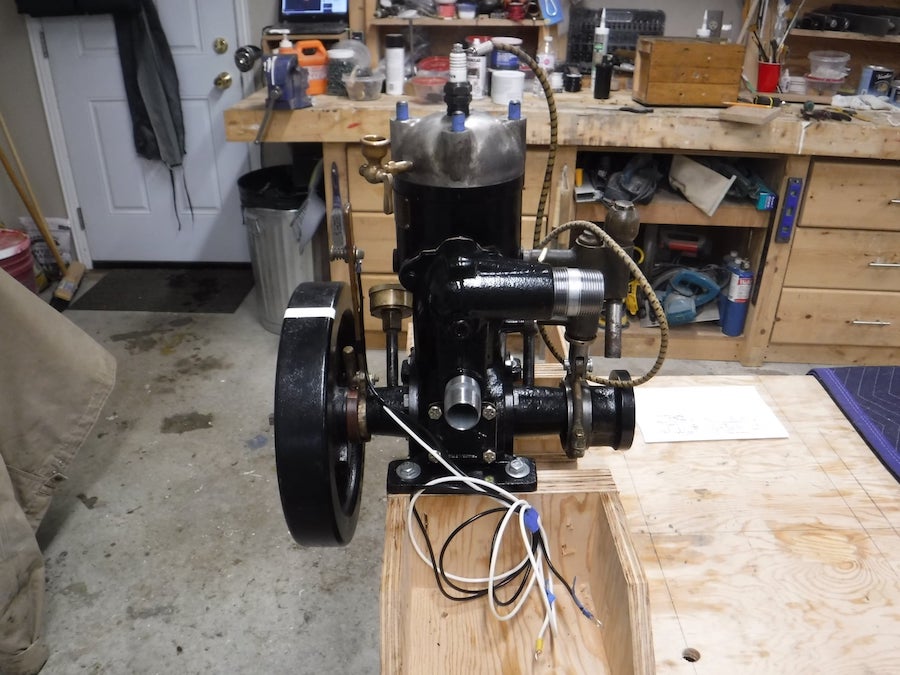

The deal went through. I'm quite happy with it. This is Ser # 5610. It is a 3 hp.

Included are a number of spares, technical data, and the notes of whoever it was that tore down the engine. Also included are parts that don't belong.

At first glance, not included are the trembler coil, flywheel and shaft flange.

At some point I'll lay things out and compare what I have to the illustrated parts list, then take it from there. I don't anticipate any insurmountable problems.

Cheers! |

ernie

Senior Member

Username: ernie

Post Number: 2639

Registered: 01-2002

| | Posted on Friday, July 16, 2021 - 05:18 pm: |

|

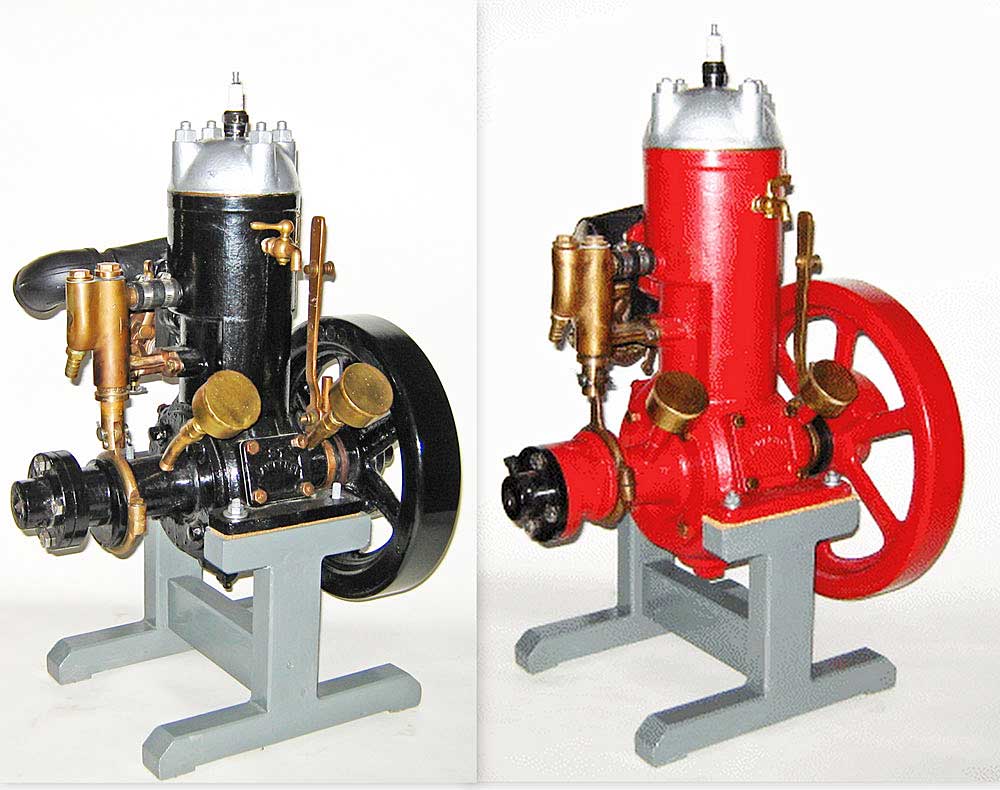

It is nice to see one with the nickle plating on the head still in reasonably good condition |

chris_spring

Senior Member

Username: chris_spring

Post Number: 119

Registered: 02-2019

| | Posted on Saturday, July 17, 2021 - 07:43 am: |

|

I'm looking forward to getting stuck into this one.

Although it is not entirely original such as the Adams, it is interesting. It also appears to be in very good overall condition, which gives me a good starting point.

I won't try to return it to "as new" condition. Rather I'll try to preserve as much of the original patina as possible.

At least that's the plan.

I'm looking forward to hearing it run.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 120

Registered: 02-2019

| | Posted on Sunday, July 18, 2021 - 07:08 am: |

|

I couldn't resist getting at it. I am quite pleased with what i see so far.

I figured a good way to get started was simply to do some sorting and cleaning. I started with the greasers. They cleaned up nicely. The grease in them was quite hard.

I pulled the carb apart to find it needs nothing save a new drain, o ring and gaskets. Barry sent me an O ring. I can make a gasket. I think I can even get by with the old float. The air horn internals are good.

I pulled the water pump apart to find all it needs is cleaning and re-assembly.

I pieced together what I believe is one complete timer plus spares. I have a trembler coil. I just need a spark plug lead. The spark plug looks original. If it works, I'll use it.

And then I went to the big ticket item, the engine itself. It had been sitting in a dusty and fairly dirty environment with both side covers off. Without further dis-assembly there is no way to determine that grit has not found its way into the bottom end, bearings or wrist pin. However, overall it looks good.

I pulled the head. The cylinder bore appears excellent.

I pulled the manifold. What I can see of the piston and rings look good.

The crank has surface rust. There is no up and down play, and very little play fore and aft.

Hardware, by that I mean bolts are either missing or incorrect but easily sorted.

Today I go in search of a flywheel and flange.

Cheers!

|

ernie

Senior Member

Username: ernie

Post Number: 2640

Registered: 01-2002

| | Posted on Sunday, July 18, 2021 - 07:54 am: |

|

Chris,

In your carb info you mention gaskets. Just wondering what gaskets? The model D carb only uses 1 O ring and no gaskets.

If the carb needs gaskets between the air horn and float bowl top to work OK something isn't flat. I sand the gasket surfaces of these flat with my bench top 12 inch disc sander. The same for the carb body/float bowl and throttle. Before sanding that surface of the throttle make very sure it is clean and absolutely dry so you can blow out all of the brass dust that got all over it and in it when you did that. The tiny vertical slot in the float bowl gasket area is a drain and should be clear. Usually any gasket between the throttle and float bowl will plug that up. Also even though the parts list shows a gasket on the cover over the float valve they seem to work better with no gasket in that circular groove around the threaded cover. And there is no float bowl cover gasket. Only the O ring in the center.

And as an information point I rebuilt a bunch of Model D carbs a few years ago by cleaning all oil and grease off then boiling them in vinegar for an hour or so. Then scrubbing all the parts with a brass tooth brush in running water. Then a good inspection of all the parts. Bary's info on the float valve and seat area was a good reminder to inspect this area real well. At this point when test fitting all the parts together just about all the areas mentioned above on just about all the carbs (about 10) needed to be sanded flat.

Hope this helps

Ernie

Hope this helps

Ernie |

chris_spring

Senior Member

Username: chris_spring

Post Number: 121

Registered: 02-2019

| | Posted on Sunday, July 18, 2021 - 05:02 pm: |

|

Ernie. I'll re-visit the whole carb thing. When I pulled the top off the float bowl there appeared to be a blue paper gasket between the two. It was about the thickness of card stock.

There was also a gasket on the float valve cover.

I'll go over it again making sure mating surfaces on such things as throttle and air horn are perfectly flat.

I'll also have a closer look at the float valve.

Thanks for the info.

Cheers! |

ernie

Senior Member

Username: ernie

Post Number: 2641

Registered: 01-2002

| | Posted on Sunday, July 18, 2021 - 06:57 pm: |

|

Here is the actual Model D manual located right here on OME. Item N is what we have replaced with an O ring. Item 10 is the cork gasket for the float valve lid/bowl cap.

http://oldmarineengine.com/technical/carburetor/scheblerD.html

All the small drawings and lists etc on the right are clickable to enlarge |

chris_spring

Senior Member

Username: chris_spring

Post Number: 122

Registered: 02-2019

| | Posted on Sunday, July 18, 2021 - 07:17 pm: |

|

Thanks Ernie.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 123

Registered: 02-2019

| | Posted on Monday, July 19, 2021 - 12:05 pm: |

|

On the subject of carburetors, the one I have has part V, flusher. What is the purpose of the flusher?

Question 2 is, can someone point me the right direction to obtain part T, drain cock?

Cheers!

|

ernie

Senior Member

Username: ernie

Post Number: 2642

Registered: 01-2002

| | Posted on Monday, July 19, 2021 - 02:43 pm: |

|

Chris,

The flusher is to make it rich for starting. The flusher actually pushes the float down so the carb floods over. I never use it as it can damage the float.

Any good real hardware store should have a 1/8 in petcock. At least that is what they call them down here in the US.

Hope this helps

Ernie |

chris_spring

Senior Member

Username: chris_spring

Post Number: 124

Registered: 02-2019

| | Posted on Monday, July 19, 2021 - 05:43 pm: |

|

Thanks again Ernie.

WRT flusher. I could see that it was there to push the float down. I just couldn't figure out why on earth anyone would want to do that?

Thanks for the tip on petcock.

Cheers! |

kingfisher

Advanced Member

Username: kingfisher

Post Number: 41

Registered: 01-2013

| | Posted on Monday, July 19, 2021 - 06:33 pm: |

|

Flooding to start is standard and recommended procedure with a Simplex. Hold down the flusher until fuel drips from the drain hole on the flange. Starts perfectly every time.

Mark |

miro

Senior Member

Username: miro

Post Number: 1140

Registered: 11-2001

| | Posted on Tuesday, July 20, 2021 - 07:04 pm: |

|

Before you put the head back on the engine, make sure that you get a good 'pop" when the piston clears the intake port. That means that you have a good seal on the crank case.

It really helps when starting .

Also, it helps to use a slightly richer mix of gas/oil to get the sealing around the piston rings.

Looks like a very good job so far.

miro |

chris_spring

Senior Member

Username: chris_spring

Post Number: 125

Registered: 02-2019

| | Posted on Tuesday, July 20, 2021 - 08:18 pm: |

|

Miro.

Will do. The covers are currently removed. I'm concerned about contamination inside the engine so I've decided to tear it down completely before re-assembling.Therefore I'll need access.

The front and rear bearings appear to be in good shape. I'm not too worried about them being a source of possible leakage.

That said, I'll certainly heed your advice and make sure everything is properly sealed as it goes back together.

Today I stole a page from Ernie's book and flattened the carb mating surfaces. I have a set of sharpening stones. I trued them up, then flattened the surfaces. I was actually a little surprised how far out some were.

At some point I'll be in the hunt for a ball cage for the suction side of the water pump. The one I have is damaged.

I'll be away from the project for a month or so. I'll chase that down when I get back.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 126

Registered: 02-2019

| | Posted on Thursday, July 22, 2021 - 07:51 am: |

|

The guys that dismantled the engine did a pretty good job of bagging and tagging parts. They also kept note wrt what goes where.

I had already intended to do a complete teardown before I read the notes. It seems that they had difficulty getting the con rod bolts undone. They used heat but still broke one. Hmmmm!

I then looked at the piston orientation. As it sits the baffle is on the manifold side. I know we've been down this road before but I have to ask the quetion. Diagrams I've seen all show the baffle on the off side. None show it on the manifold side. Am I correct in stating that they re-installed the piston with the baffle on the wrong side?

And while I'm at it. The thrust bearing, flange and flywheel are not installed. Included were 3 thrust bearings,none of which I will attempt to use.

It is my unterstanding that the thrust bearing, flange and flywheel are pressed on. Does that require the services of a machine shop or can they be installed with a block of wood and a mallet?

Cheers! |

miro

Senior Member

Username: miro

Post Number: 1141

Registered: 11-2001

| | Posted on Thursday, July 22, 2021 - 10:26 pm: |

|

Yes, it looks like the piston is installed 180 deg from what it needs to be.

Also, see if you can get as much of the schmutz inside the water jacket out of there especially the 2 small ports near on of the studs. Those ports connect to the 2 ports on the head, so make sure you've got the head on the right way so the ports match. |

chris_spring

Senior Member

Username: chris_spring

Post Number: 127

Registered: 02-2019

| | Posted on Sunday, July 25, 2021 - 11:31 am: |

|

I'm now feeling a little embarassed over my piston orientation question. This is my first exposure to the finer workings of a 3 port engine.

Barry's thumbdrive info is very clear on that subject. Clearly I didn't understand how a three port system works even though it is so basic. I should have delved through Barry's info before posing the question.

Sorry.

Cheers! |

miro

Senior Member

Username: miro

Post Number: 1142

Registered: 11-2001

| | Posted on Tuesday, July 27, 2021 - 08:25 pm: |

|

Here's the video of the cranks case "pop"

https://www.youtube.com/watch?v=26ZqocIaS5w

miro |

chris_spring

Senior Member

Username: chris_spring

Post Number: 128

Registered: 02-2019

| | Posted on Tuesday, July 27, 2021 - 09:36 pm: |

|

Does the installation of the flywheel, thrust bearing and flange require any special tools or skill?

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 134

Registered: 02-2019

| | Posted on Sunday, August 08, 2021 - 09:00 pm: |

|

I'm still hoping to get advice wrt my question above.

Cheers! |

bcm

Senior Member

Username: bcm

Post Number: 139

Registered: 11-2009

| | Posted on Wednesday, August 11, 2021 - 03:29 pm: |

|

Chris,

This from Barry Millar in response to your question about St Lawrence assembly.

Flywheel and water pump eccentric are straight bore with interference fits and keyways. Flywheel uses Gib key, eccentric uses Straight key.

As flywheel is not from your engine be sure to check fit .

You can rig two threaded rods for assembly. Always position the keys during assembly to ensure keyways are aligned with keys.

It is prudent to support the crankshaft webs during the assembly process. Use a 3/8" coupling nut with 3/8" capscrew for this purpose.

Review SUBJECT 5 noting one half of the thrust bearing is a tight fit on the 1.125" crankshaft, the other half is 1.150 thus is clear of the shaft. The clear side is against the bearing housing as illustrated SUBJECT 5.

Water pump band must be positioned on the eccentric before assembly not after. The water pump piston also should be in place. Band shim can be adjusted for best fit after assembly is done.

Be sure to examine water pump piston and drive pin, refurbish as required. Drive pin and band can be repaired if needed by reaming the band to 17/32 and making a new matching pin. I have 17/32 material and a 17/32 reamer that you can borrow. Might be wise to make a new piston if yours is pitted.

Best to repack the pump before assembling the eccentric. 3/32 square graphite impregnated packing is required, five packing rings . I have some extra packing. 3/32 is hard to find.

Suggest you review SUBJECT 10. This illustrates the old style eccentric and drive band. Your engine uses the new style that was introduced about 1940 thus originally your engine was fitted with old style. ???

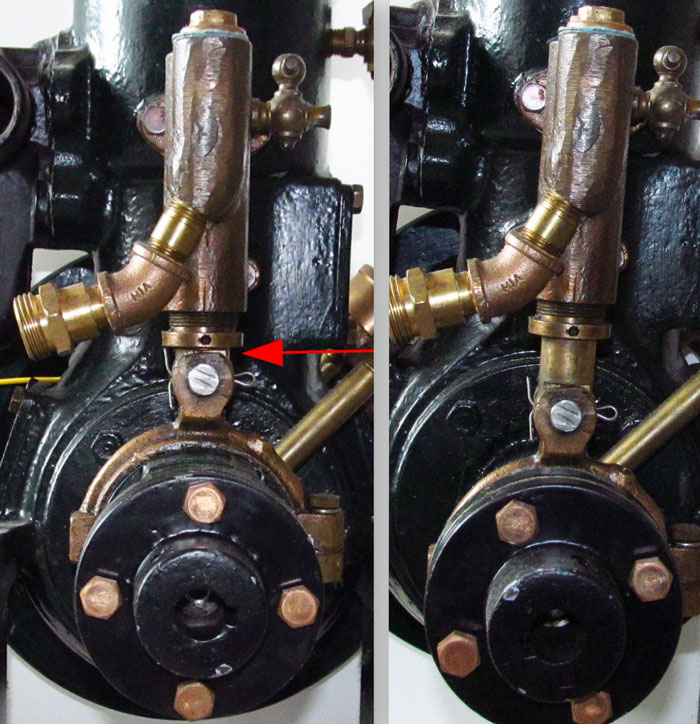

I've attached images of the new style pump. Note red arrow left side image where water pump piston is a top of stroke. There must be clearance between the band and packing nut. If band strikes packing nut pump may be damaged beyond repair.

To assemble, first pack grease into thrust bearing then push bearing onto shaft noting that bearing is tight fit.

Pull or push eccentric onto shaft with key in place until crankshaft throw is approximately centred between housings.

Assemble timer lever onto bronze bearing extension then pull or push flywheel onto crankshaft until there is about .005 endwise clearance. First note condition of commutator, not important if you plan to use electronic sensor, very important if you plan to use brush sensor. I have new commutator if needed.

Check Miro's recent post re brush housing, also this 2006 ome thread re electronic sensor.

http://www.oldmarineengine.com/discus/messages/3457/96400.html

Another advantage , the electronic sensor provides an input to a digital tachometer, Tiny tach for example, in my opinion a must have.

When assembling flywheel be sure to push against eccentric end of crankshaft not against eccentric so as not to disturb eccentric position.

Finally hammer gib key to lock flywheel.

Regards

Barry

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 135

Registered: 02-2019

| | Posted on Wednesday, August 11, 2021 - 07:08 pm: |

|

Thank you again Barry. It will be a few weeks until I can get back to the project. In the meantime I am trying to get parts sourced and develop a clearer understanding of what is required. You've clarified that the services of a machine shop are not required to install the thrust bearing, water pump eccentric and flywheel. That is helpful.

Cheers!

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 140

Registered: 02-2019

| | Posted on Friday, August 27, 2021 - 08:17 am: |

|

So here's the thing. When I inspected the engine prior to buying it, I realised that I was pretty much buying a collection of parts which amounted to about 80% of a complete engine.

When I got it home I partially disassembled it to further inspect. That revealled a damaged water pump cage valve, a piston installed backward,and a few other things.

The other day I removed the piston to find a badly corroded crankshaft throw.

Whereto from here? I'm not sure. I've been in contact with a machine shop who I am hoping will tell me that they can make the whole problem go away at a price within my snack bracket.

We'll see. If not I'll need a plan B.

Buyer beware! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 142

Registered: 02-2019

| | Posted on Monday, September 06, 2021 - 12:55 pm: |

|

This past week I delivered the crankshaft and piston to a machinist some distance away. He seemed familiar with old marine engines. His proposed fix for the crankshaft pitting is to build it up with weld, then grind it down to spec. He will then ream the con rod big end to fit.

He said I should expect about a two week wait. Cost was not discussed since I am now pretty committed to this project. I figure if he can get me back in the game, this engine should run well beyond my lifetime.

I had originally planned to assemble the engine without painting. Now I am seeing that as it cobbles together it looks rather tough. I don't know where this engine will end up, but its getting paint. If I sell it, no doubt people will be looking for something shiny. If nothing else it will prevent further deterioration.

I am still in the hunt for a flange, water pump, or at least the cages and drive pin.

As well, there was only one air valve cap screw (part 2 on the illustrated parts diagram). The one included is not original, so I guess I could use a pair of those.

If anyone has these parts to sell, I'd be interested in hearing from you.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 143

Registered: 02-2019

| | Posted on Monday, September 06, 2021 - 02:51 pm: |

|

I've done a little more puttering. In the process I determined that there was only one throttle cap screw, (part 5) and it was steel as opposed to brass. I'll be adding a pair of those to my "wants" list.

I also took the time to de-glaze the cylinder. Upon initial inspection the bore appeared to be in good shape. Today, all it took was a couple of minutes with the cylinder hone and it was done. As the glazing was coming off it did so evenly, and there was no scoring or pitting to be seen.

I'm calling that a win.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 146

Registered: 02-2019

| | Posted on Saturday, September 18, 2021 - 11:42 am: |

|

My parts came back. The machinist did a very nice job at a price I thought was within reason. I will slowly come at re-assemby as time and parts permit.

As Miro said, I took on a project. I knew that. However, if I can get it back together and running, it will no doubt outlive me. That, in a way, is pretty cool.

As well, this engine will provide me a backup if I decide to swap out the Adams engine in the Gidley.

Cheers! |

bcm

Senior Member

Username: bcm

Post Number: 140

Registered: 11-2009

| | Posted on Wednesday, September 22, 2021 - 05:27 pm: |

|

Chris,

Further to my Aug 11 post:

When assembling the eccentric and flywheel you can rig a 2 ton bottle jack between threaded rods.

Or your machine shop would have a hydraulic press.

I've done this many times. The hydraulic jack facilitates precise assembly.

A suitable bottle jack is $28 at Amazon.ca.

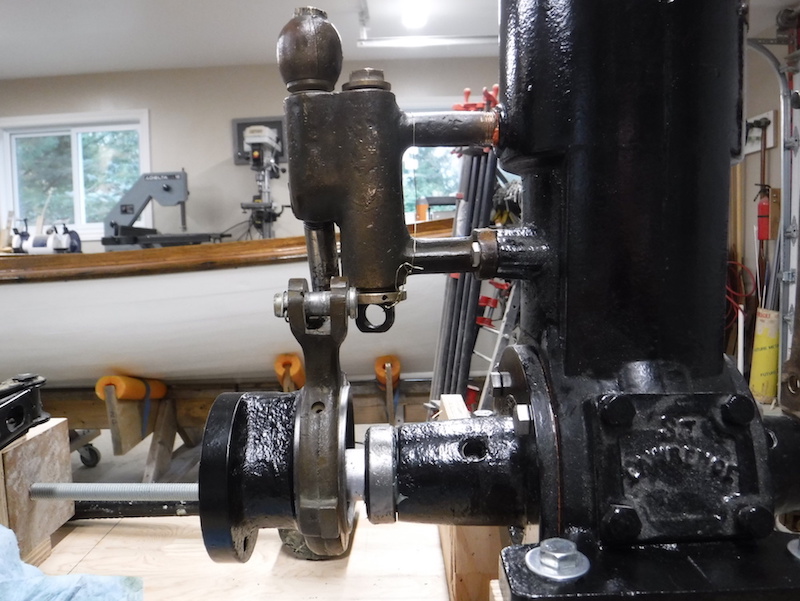

Incidentally have you verified the wrist pin condition? I've attached an image that illustrates wrist pin rework that is suitable for cast iron pistons as is the arrangement with your St Lawrence.

Suggest you check SUBJECT 14 item 6.

Maybe Ernie might add to this?

Barry

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 147

Registered: 02-2019

| | Posted on Wednesday, September 22, 2021 - 06:52 pm: |

|

Hi Barry.

Thanks for the "how to" on installing the flywheel and eccentric. I'll give it a go. If not, I can always take it to the machine shop. The guy I found is quite a distance away but I trust him and I think his price is fair.

The wrist pin appears to be in good condition. I considered it carefully then decided to leave it alone.

I am about to start re-assembly. I'm still missing an ignition lead and a coupler,but I am hoping that will sort itself out.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 169

Registered: 02-2019

| | Posted on Friday, November 12, 2021 - 03:04 pm: |

|

I am ramping up toward assembling the St. Lawrence.

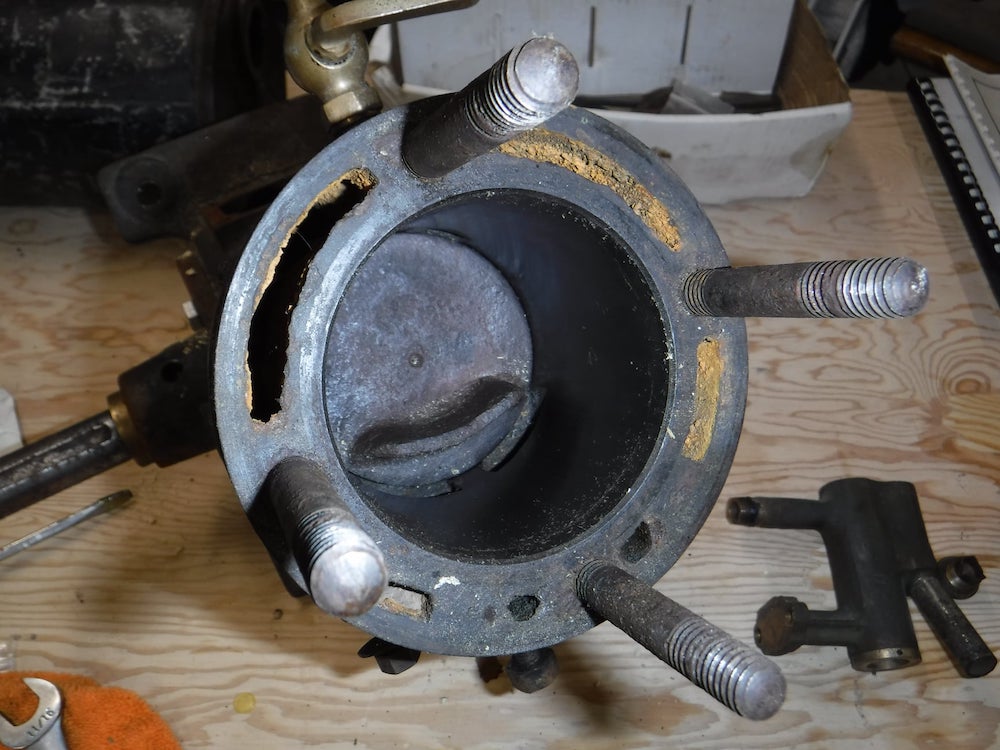

I have seen it written where the water pump should be installed before pressing on the eccentric. So I thought I'd trial fit everything. It is probably a good thing I did. You can see from the pic the water pump band (bridle) will not allow for a complete revolution of the crankshaft. In fact it is not even close.

If I back up in this thread I can se a pic of one of Barry's engines with the newer style band. Even it looks different to the one I have. He also shows two pics with the old style band.

The good news is that Audie provided me a serviceable old style band. The problem is that I don't have a serviceable piston to go with it.

So here are my questions.

What engine does the new style band I have fit?

What is the downside to having a piston made and going with the old style band?

What say you?

Cheers!

|

bcm

Senior Member

Username: bcm

Post Number: 141

Registered: 11-2009

| | Posted on Saturday, November 13, 2021 - 10:26 am: |

|

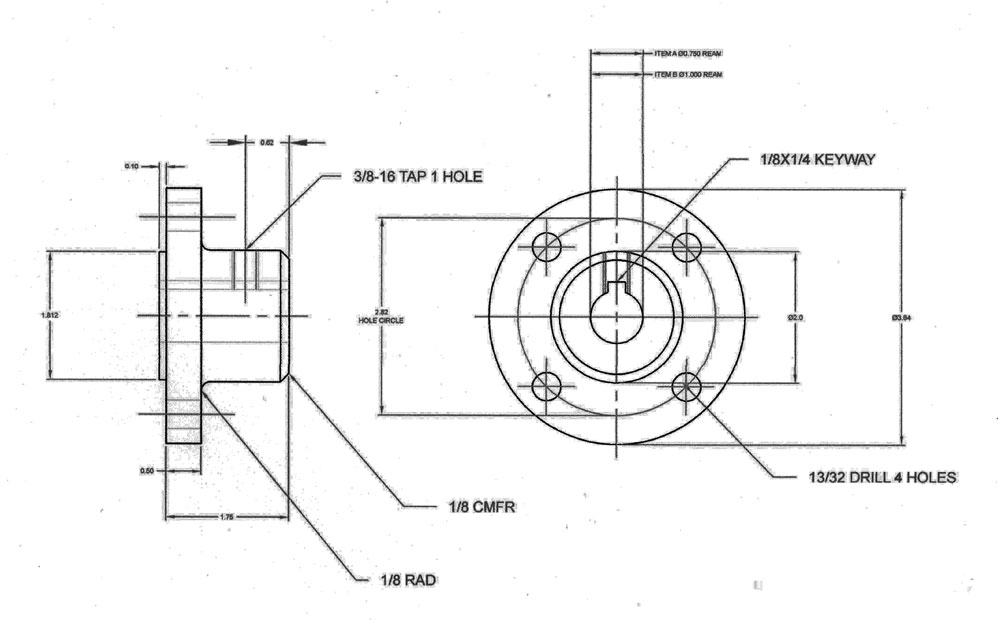

Chris,

Your engine originally used the old style pump. The eccentric has shoulders,refer to my post Jan 10 2021.

Your pump band fits the 3 1/2S x 4B engine. As you have discovered does not fit your engine.

I have the correct band plus other part. Refer to image. The longer bronze cap screws will suit your Schebler cap.

2nd image is a machining drawing for the coupling. Let me know if you wish to have a full size drawing. I will send it by snail mail.

regards Barry

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 170

Registered: 02-2019

| | Posted on Saturday, November 13, 2021 - 12:03 pm: |

|

Thanks for the drawing Barry. I will hand it off to my machinist later together with a couple of other small jobs I have for him.

Audie provided me a serviceable old style band. Interestingly it is two piece like a connecting rod, as opposed to one piece and shimmed. It can be installed after engine assembly.

I lack a piston for the old style band. If yours is for sale I will happily take it. Otherwise I'll have one made.

I have already sourced screws for the carb. Thanks.

For water pump packing I'm going to go old school. I have greased a length of lamp wick. Lamp wick is working fine on the Adams pump as well as the stuffing box.

Oh, and while we're at it, two things.

Just to confirm the contact goes opposite the counterweight on the flywheel? I recall reading that somewhere but can no longer find that reference.

My brand new thrust bearing simply slid on. No pressing required. Is that a problem? My guess is not.

Cheers! |

bcm

Senior Member

Username: bcm

Post Number: 142

Registered: 11-2009

| | Posted on Saturday, November 13, 2021 - 12:45 pm: |

|

Chris,

I do not have a piston for old style pump.

Re your question about contact position you are correct.

Be sure to use gaskets when you install bearing housings. Fel Pro 3042 1/32" from Amazon.ca is ok.

Barry |

bcm

Senior Member

Username: bcm

Post Number: 143

Registered: 11-2009

| | Posted on Saturday, November 13, 2021 - 01:28 pm: |

|

Chris,

Regarding thrust bearing maybe try dinging the crankshaft at four places at 90 degrees so bearing is snug.

At final water pump assembly use pipe dope with PTFE (Teflon). When the thread is tight, if there is a gap under the flange use a shim to fill the gap.

Barry |

chris_spring

Senior Member

Username: chris_spring

Post Number: 171

Registered: 02-2019

| | Posted on Tuesday, November 16, 2021 - 02:14 pm: |

|

Rather than fooling around I located some bar stock and made a piston. I think I'm good to go.

I'm not sure when I'll get serious about assembling the engine. I have a few things in the queue ahead of it. However I'd like to have everything I'll need on hand when the time comes.

Audie. Without the parts you sent me I'd still be dead in the water so to speak. Many thanks.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 172

Registered: 02-2019

| | Posted on Sunday, November 21, 2021 - 04:17 pm: |

|

Question du jour. The nut on the manifold. The one that was on there was steel. Should it be brass? Ditto the cap screw?

The last two pics are where it sits as of today. Before I permanently install the cylinder head I'll get a new gasket. As well I'll test the crankcase to ensure I'm getting a good seal.

The carb needs a bit of work too. The pipe thread to the manifold is damaged. I'll either repair or replace. I'll also throw a new float at it.

It is coming along. I will likely get to the ignition system this week.

Cheers!

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 173

Registered: 02-2019

| | Posted on Sunday, November 28, 2021 - 06:55 pm: |

|

The St.Lawrence is coming along. With help from Miro I now have a serviceable ignition system. I have one change I am going to make which will eliminate the need for the white wire shown in the second pic, but that's about it.

In the background of the second pic you can see the ignition box from the Gidley where I'll house the Miro 2000 ignition system.

I'm left with a damaged pipe thread on the carb adapter which I hope to have resolved this week.

I have a used cylinder head gasket, and the engine still has its original carb float. I'm thinking that if I can get the carb to function properly with the old float, I might use the old cylinder head gasket to get the first run out of it. Then, based on how that goes, I'll likely order a new float and gasket from Otto's.

Miro advised me when I was considering buying the engine that I was taking on a project. I knew that, but he was exactly right. Considering what i have tied up in it, it makes no economic sense, but I don't care. I just want to hear it run.

I may not be too far from that. Its been fun.

Cheers!

|

chris_spring

Senior Member

Username: chris_spring

Post Number: 174

Registered: 02-2019

| | Posted on Monday, November 29, 2021 - 07:37 am: |

|

I've re-thought the white wire thing. I was going to simply jump it from the timer contact to the black wire on the timer button. Dumb idea. Not sure what I was thinking. I was tired. What can I say? The white wire stays as is.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 175

Registered: 02-2019

| | Posted on Sunday, December 05, 2021 - 10:20 am: |

|

This morning I got a couple of very encouraging runs out of the st. Lawrence. It is not difficult to start. And it seems to run well using the old carb float, and guessing as to where the mixture and air valve settings should be.

After about the third short run I couldn't re-start it because the ignition system went dead, no buzzing. I'm not sure how or why that would be, and only occur after shutdown, but I'll try to sort it this week.

In the meantime 3 hp ser# 5610 is alive and well. It is no longer a collection of parts.

Cheers!

|

miro

Senior Member

Username: miro

Post Number: 1169

Registered: 11-2001

| | Posted on Sunday, December 05, 2021 - 11:38 am: |

|

There's an old expression with old marine engines . . . it's always the timer . . . . but maybe not in this case.

You're persistent / relentless and will find out why.

Does it hop around much?

The old float will be OK for a while, until it has absorbed enough fuel, after losing the shellac coating due to the 10% alcohol . But for the moment it'll be workable. Maybe you can drain the fuel from the bowl, when you're not fooling with the engine. |

narrabay2

Senior Member

Username: narrabay2

Post Number: 227

Registered: 10-2019

| | Posted on Sunday, December 05, 2021 - 12:08 pm: |

|

As to the float, is there a alcohol proof dip that it can be coated with? |

chris_spring

Senior Member

Username: chris_spring

Post Number: 176

Registered: 02-2019

| | Posted on Sunday, December 05, 2021 - 03:03 pm: |

|

Miro.

I'm not too worried about the ignition thing. I'll sort it.

A new float is on order from Otto's. It should be here within a couple of weeks.

I might run the engine a couple more times in order to do some carb adjustments, and quite simply just to hear it run.

As I was putting it away today I drained both fuel and water.

The engine runs quite smoothly. It wanted to hop around a bit for the length of time it took me to close the compression release and advance the timing but after that it was good. I think that is remarkable since I could only ballpark where to set the fuel mixture and air valve. Also, that needle valve is not for that carburetor, but it works.

I'm pleased as can be. Like I said, I'll likely run it again, then it will be put away. It is nice to know that a) it is no longer simply a collection of parts, and, b) I could very well have saved it from the scrapper.

Cheers! |

chris_spring

Senior Member

Username: chris_spring

Post Number: 177

Registered: 02-2019

| | Posted on Friday, December 17, 2021 - 02:09 pm: |

|

During subsequent troubleshooting it took little time to find the ignition problem.

During the restoration I gave most metal parts a pretty liberal coat of black paint. When I assembled the ring on the back of the flywheel, I didn't bother cleaning off the paint in the area of the copper contact. I reasoned that the screw going through it to the flywheel would provide a good enough ground. When I tested it, it did. It appeared nothing was amiss. The screw as it turns out is slightly undersize with the result that it did not provide a good enough ground.

The way I found this out was that by the process of elimination, when I had no ignition, if I grounded across the timer, it would work. If I took a brass shim and worked it between the ring and the flywheel such that it touched both the contact and the crankshaft, it also worked. Ergo the contact does not have a good ground between it and the flywheel.

The only thing for it was to once again pull the flywheel. It was then, after I'd removed the ring, that the reason for the fault became obvious.

I have now cleaned away the paint on the flywheel in the area of the contact as well as that which found its way into the screw holes. I have now re-assembled it and tested it. I am sure it will work.

What I also did this time was add a very judicious amount of gasket compound to the inside of the ring such that it will prevent any grease that happens to seep out of the front bearing from migrating into the crack between the ring and flywheel and outward onto the contact.

I hope to re-assemble the whole thing perhaps this weekend, but i'm pretty confident I've found the problem.

My new carb float also arrived from Otto's. I installed it this morning.

Whether I bother to run the engine again, other than on prime I'm not sure, but before I put it away I'll make sure ignition is no longer an issue.

Cheers!

|