| Author |

Message |

dick_briggs

Senior Member

Username: dick_briggs

Post Number: 51

Registered: 02-2015

| | Posted on Monday, February 14, 2022 - 04:13 pm: |

|

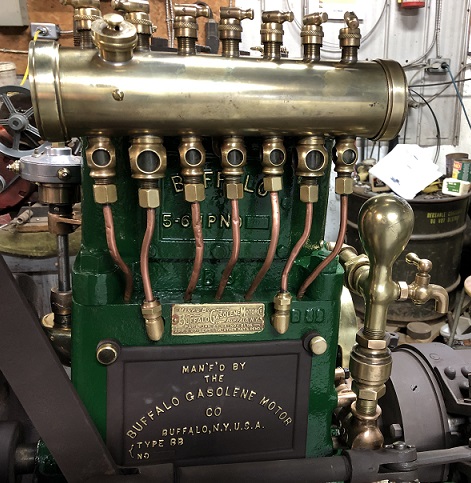

I have a two cylinder, two hp Buffalo, #266 with some features that seem different from others on this site. (Figs. 1, 4)

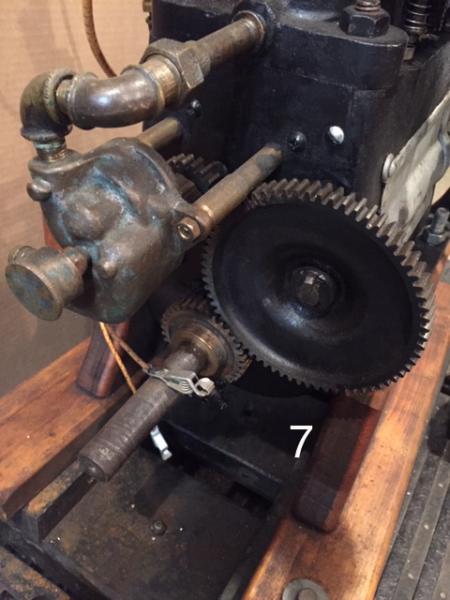

The water pump is a gear driven rotary pump, not the usual piston type driven by an eccentric behind the big gear. Mine has no eccentric nor does it have any room for one, and all the gears seem to be properly spaced. Also the piston pump is fastened to the block by four bolts, mine has an upper boss drilled for two and the lower boss has room for, and is drilled for, only one. (Figs. 7, 8, 9)

I thought at first the Cuno timer was a replacement for the missing proper one driven by bevel gears, but perhaps it is original. The length of the crankshaft end is pretty long, allowing for a big space between the block and the flywheel as would be needed for the Cuno timer but not the other one. And this would not be an easy modification to make after the fact so maybe it is original. (Figs. 2, 5)

|

dick_briggs

Senior Member

Username: dick_briggs

Post Number: 52

Registered: 02-2015

| | Posted on Monday, February 14, 2022 - 04:16 pm: |

|

Sorry, here is the correct Figure 5

|

miro

Senior Member

Username: miro

Post Number: 1178

Registered: 11-2001

| | Posted on Tuesday, February 15, 2022 - 11:38 am: |

|

The interesting thing is that it has 2 oilers - seemingly for cylinder lubrication.

For a 4 cycle engine, it seems a bit redundant, but maybe this engine was part of the transition to oil in gas mixing and was simply a fluke of history.

Looks to be in very good shape.

Is it a runner?

Do you have a history of the engine?

miro |

dick_briggs

Senior Member

Username: dick_briggs

Post Number: 53

Registered: 02-2015

| | Posted on Thursday, February 17, 2022 - 05:39 pm: |

|

Miro, Thank you for your thoughts. I don't have any history of the engine; it came from a gentleman in eastern MA. The two oilers are interesting, but they seem to be on all the Buffalos I have seen in pictures and one in person. It turns over easily and has good compression. The man said he had run it and it looks like it has been run, but I have not yet as I am not sure about the lubrication system. There is a drain from the crankcase beneath the water pump, but there is no obvious (to me) place to check the oil level. The plate on the side (see Figs 10, 11) doesn't appear to be original but is nicely done. It has a flip top oil cup and below it what might be an oil filler fitting (if so, why the flip top oiler?) or perhaps it serves as a crankcase breather (note the hole drilled in the cap). I guess I am going to have to remove that plate and look inside.

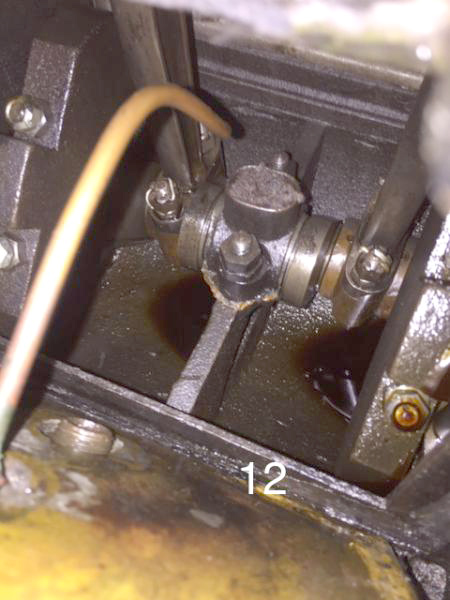

Another interesting feature is that both pistons are in synchrony - both in the same position in their cycle at the same time; for example they are both at top dead center at the same time. I'm sure there is a name for this, but I don't know what it is. The spark plugs fire alternately from the two posts on the Cuno timer and the double buzz coil. One might expect some serious vibration but there is no counterweight on the flywheel -- we'll see. |

miro

Senior Member

Username: miro

Post Number: 1180

Registered: 11-2001

| | Posted on Saturday, February 19, 2022 - 12:57 pm: |

|

The "synchrony" that you describe is what the English 2 cylinder motorcycle engines use, and maybe the Japanese ones too ( never dealt with the Japanese bikes).

The firing is alternate, and the compression stroke opposes the power stroke so it wouldn't be as bad as if the engine were a 2 cycle with "synchrony"

Overfilling the case is not a good idea and I suspect that there's quite a bit of splash when running.

Inside the case there's more like a "fog" of oil all over the inside of the case.

The base of that breather cap is well above the centre line of the crankshaft, so the throws will be surely dipping into the oil.

miro |

bgoss

Senior Member

Username: bgoss

Post Number: 280

Registered: 12-2007

| | Posted on Saturday, February 19, 2022 - 02:42 pm: |

|

Attached are a couple pictures of a 5-6hp that we used to have. Your pump and gear arrangement is definitely different. When you take the fabricated plate off the crankcase, I believe that you will find two tubes leading from the oilers to low on the cylinders. On ours, the oil lines led to the mains, and dripped onto the throws. You may also find that there are counterweights on the throws to account for the pistons.

Blair

.

.

. |

ernie

Senior Member

Username: ernie

Post Number: 2673

Registered: 01-2002

| | Posted on Monday, February 21, 2022 - 01:29 pm: |

|

The engine posted by Dick B was mine. When I got it it was basically a long block with no accessories. The water pump came from a Universal 1 cylinder fisherman.

The side cover I made. The breather is just that as both pistons go up and down together a breather is needed. The flip top oiler by the breather is to get oil to the center main bearing prior to starting. Once running it is splash lubricated. the front and rear mains are pre lubed at the felts that protrude from the crankcase on each end.

I also put the Cuno timer on it. Buffalo made their own timers. Finding one isn't easy.

Buffalo had cylinder skirt oilers on all of this style of engine.

The oil level should be set so the bottoms of the connecting rods just dip into it.

Funny how these things show up. I did the work on this engine back around 1990 or so. I always wondered where it went.

Ernie |

ernie

Senior Member

Username: ernie

Post Number: 2674

Registered: 01-2002

| | Posted on Monday, February 21, 2022 - 01:32 pm: |

|

Miro,

By the way it is a 4 stroke. No oil in the gas.

Ernie |

ernie

Senior Member

Username: ernie

Post Number: 2675

Registered: 01-2002

| | Posted on Monday, February 21, 2022 - 01:38 pm: |

|

Dick,

The little hole by your number 8 is to pre lube the rear cam bearing. There is also another hole in your number 2 between the carb and timer for the front cam bearing.

When I got it the flywheel was real close to the front of the block. I just moved it out on the crankshaft to give me room for the Cuno timer.

This engine may have been a stationary version hence no place for or evidence of a water pump. May also be the reason for the long snout on the front of the crankshaft.

Ernie

Ernie |

bgoss

Senior Member

Username: bgoss

Post Number: 281

Registered: 12-2007

| | Posted on Monday, February 21, 2022 - 04:04 pm: |

|

That explains a lot. The engine world is pretty small. Thanks Ernie. We were also wondering if it could have been a stationary unit. |

ernie

Senior Member

Username: ernie

Post Number: 2676

Registered: 01-2002

| | Posted on Monday, February 21, 2022 - 08:58 pm: |

|

The guy I got it from had another one that was defiantly stationary, with a nice little fly-ball governor and no water pump.

I tried to buy it for years with no luck. |

dick_briggs

Senior Member

Username: dick_briggs

Post Number: 54

Registered: 02-2015

| | Posted on Tuesday, February 22, 2022 - 10:40 am: |

|

Hi Ernie,

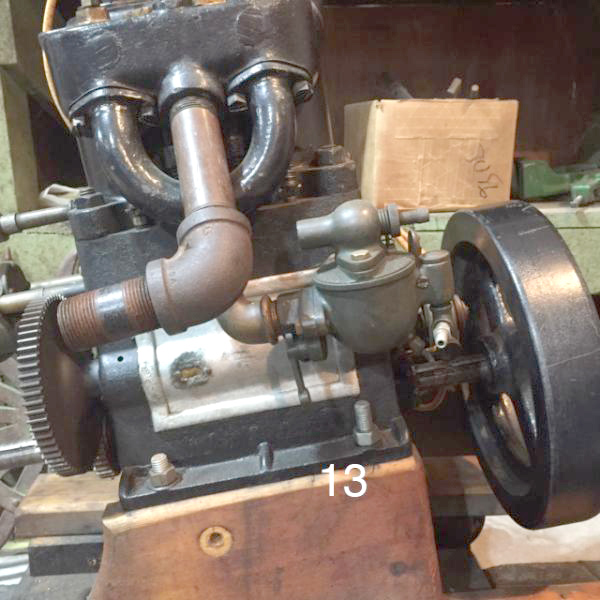

Well, it does explain a lot and I should have known! There sure are a lot of engines in the northeast that have passed through your hands. I was recently saying to Andrew that these engines often hold so many mysteries: who did that, how/when/why was that done, is it original, etc. You did a really terrific job on this one. I did take the side panel off and was starting to understand more, but thanks for your help and the additional pointers about lubrication. The bottom of the crankcase has a low divider across it so there are two pools of oil there for splash lube by the counterweights on the crank. Since the engine is mounted at a slight angle, oil tends to drain and pool mostly at the rear (Fig. 12). Would splashing by the rear counterweight be enough to do the entire system do you suppose? It also made me wonder about the tilt of these engines affecting the carburetor function. The intake manifold has the Schebler mounted on it, and since there is the tilt, it sits at an angle (Fig. 13). Is this OK for a float type carb? Well I guess it must be since it is a running engine!

Thanks to all for your help.

|

ernie

Senior Member

Username: ernie

Post Number: 2677

Registered: 01-2002

| | Posted on Friday, February 25, 2022 - 06:16 am: |

|

Dick,

The carb will most likely work ok the way it is. However it is gives problems shorten the long pipe nipple on between the block and the el bow in the exhaust and orientate the carb straight out to the side. Then you can just twist it on the pipe threads so it is level. I think that was the way I originally had it.

As to oil level/s I wouldn't worry too much about it. If there is some in there geting flung around by the crank it will most likely suffice the way you will be running it. Also some of the oil from the oilers will drip off the piston skirts and get flung around. Just don't forget the cam bearings.

Ernie

By the way did you get it from Ross? |