| Author |

Message |

ronj

New member

Username: ronj

Post Number: 1

Registered: 11-2008

| | Posted on Friday, May 29, 2009 - 08:16 pm: |

|

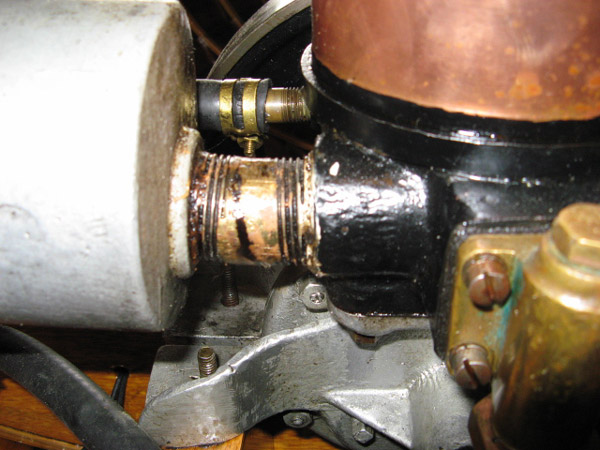

I have a 1919 Kingfisher with oil leaking at the connection to the muffler. The issue is that the connecting pipe contains a bend to allow the muffler to exhaust at the correct hull location.

If I tighten the muffler, I can probably stop the oil from leaking out the threads, but then the muffler won't line up with the hull.

Can anyone suggest a product that can be used to seal the threads and prevent the oil from leaking? But won't melt or burn off due to exaust heat.

Here is a picture to give you an idea of the setup.

Thanks,

|

miro

Senior Member

Username: miro

Post Number: 378

Registered: 11-2001

| | Posted on Sunday, May 31, 2009 - 11:01 pm: |

|

That's probably the hottest part of the engine.

Any kind of sealant will likely last only a short while.

Is there any hope of aligning the outlet of the muffler.

The outlet is SIGNIFICANTLY cooler that the inlet because of the cooling effect of the water being pumped into the muffler.

It looks like a Maxim mufffler - in those mufflers about 30% of the water goes down the drain and back into the lake the remaining water goes out the exhaust port.

If the boat is a DisPro , then you really shouldn't need the offset pipe nipple.The alignment is don't at the outlet.

You should be able to put your hand on the muffler

and not get burned.

If it is hotter than that, maube the water pump needs some tweaking.

miro |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 455

Registered: 07-2002

| | Posted on Monday, June 01, 2009 - 09:34 pm: |

|

Do you think a union would give enough for the alignment, with it in place you could tighten all the threaded joints and tighten the union after. |

ronj

New member

Username: ronj

Post Number: 2

Registered: 11-2008

| | Posted on Tuesday, June 02, 2009 - 12:25 pm: |

|

Miro: You are correct in that it is the hottest part of the engine. The muffler is an A.D. Fisher and as you suggested much of the water passes through the muffler draining out the bottom to an outlet in the hull. Also keeping it cool to the touch.

Unfortunately the threads on the input end of the muffler are not centered, so without an offset on the input pipe the exhaust aligns below the waterline. I use the offset pipe on the input side and a short length of rubber hose on the outlet side of the muffler to align above the waterline.

But I get the burned fuel oil leaking from the threads of the input pipe.

I have come up with an approach I will try this summer. I purchased some fireplace door gasket material or rope. I have been able to unravel the cord and use lengths of the threads to wrap around the pipe, not unlike how you would wrap teflon on plumbing fixtures. My hope is that the thread will withstand the heat and stop any oil flow.

Ron |

ronj

New member

Username: ronj

Post Number: 3

Registered: 11-2008

| | Posted on Tuesday, June 02, 2009 - 12:30 pm: |

|

jb_castagnos: I like that idea. As you will see in a previous post I am trying something else right now and should know within a week if it is working.

But the union approach is one I never thought of. I'll see if I can find something that will fit. I don't have much room. It would certainly make the alignment easier and would ensure I could get the pipes fully tightened.

Thanks for my plan B.

Ron |