| Author |

Message |

miro

Senior Member

Username: miro

Post Number: 932

Registered: 11-2001

| | Posted on Wednesday, October 04, 2017 - 09:15 am: |

|

Over the past 2 months or so, I've been fussing with the 2 cylinder St Lawrence engine, trying to get it to run "right".

I've done just about everything I could think of, but it still coughed, spit and mis-fired no matter what - ignitions, carbs, gaskets, timers etc etc.

In retrospect, it also ran cold - never warmed up even when I ran it out of the water for a short time.

Standing at the stern looking forward, the engine (today) turns clockwise. I set it up that way , because I have a prop that needs to turn that way - thinking that this is an older 2 cycle engine that will run in either direction.

Yesterday, I thought, how does this engine run when running "backwards" ?

Well, golly gosh darn, if the engine didn't run as right as rain ! It started easily, ran smoothly, was controlled, no backfiring, got warm like an engine should.

So now I'm on the hunt for a 12 x 12 lefthand prop which I think I've located ( thanks Barry).

Over breakfast this morning, I contemplated why this was happening - and I suspect that the crank throws might not be exactly 180 degrees apart and the engine was designed to have a preferential direction of rotation even though it will (sort of) run in the other direction.

One of life's lessons . . . persistence helps a lot

miro |

bruce

Senior Member

Username: bruce

Post Number: 624

Registered: 07-2002

| | Posted on Wednesday, October 04, 2017 - 01:23 pm: |

|

Miro, Is this a one off phenomenon peculiar to your engine?? |

ernie

Senior Member

Username: ernie

Post Number: 2404

Registered: 01-2002

| | Posted on Wednesday, October 04, 2017 - 03:05 pm: |

|

I bet it is due to the existing wear in the engine.

It most likely ran clockwise.

Now running counter clockwise the pistons rings etc are running on what was the non thrust side and seal better.

What ever you get the point. I may have confused the way the clock turns...

I have seen it several times over the years.

Enjoy the confusion...

Ernie |

miro

Senior Member

Username: miro

Post Number: 933

Registered: 11-2001

| | Posted on Wednesday, October 04, 2017 - 06:59 pm: |

|

Found a left hand prop today - it, of course, has a different taper than the one I had before, so a bit of machining to make an adapter is in order.

But with some luck and good weather in the next couple of days, I'll see how it turns out ( pun intended)

miro |

ernie

Senior Member

Username: ernie

Post Number: 2405

Registered: 01-2002

| | Posted on Thursday, October 05, 2017 - 05:57 am: |

|

Miro,

They make bushings for that. The price is very good so before spending the time on the lathe see if what you need is commercially available.

Hamilton Marine is one supplier. They are available in nylon and brass. I have used both and for the price nylon is the way to go. There is a nylon one in my launch and it has been there for about 10 years with no problem.

Here is a link to the 1 by 3/4

https://shop.hamiltonmarine.com/products/bushing-propeller-tapered-nylon-reducin g-1--to-3-4--1046.html

Hope this helps

Ernie |

miro

Senior Member

Username: miro

Post Number: 934

Registered: 11-2001

| | Posted on Saturday, October 07, 2017 - 08:49 am: |

|

Yes Ernie - that helped a lot - the link shows the SAE Standard of 1:16 for the USA made small props. My old prop was Canadian made with a different taper (ugh).

My challenge was that with our Thanksgiving weekend, it would take over a week to get here.

So, I machined one with the Canadian taper inside and the USA taper outside - took about an hour or so. Plus I learned a lot about tapers and how to machine them.

New (old) prop is now on the boat ready to go.

miro |

keith

Senior Member

Username: keith

Post Number: 507

Registered: 02-2002

| | Posted on Saturday, October 07, 2017 - 05:20 pm: |

|

Miro, So what is the Canadian taper? Compared to the US. |

miro

Senior Member

Username: miro

Post Number: 935

Registered: 11-2001

| | Posted on Sunday, October 08, 2017 - 08:09 pm: |

|

The taper for the Cdn prop ( made in Owen Sound) is 1.58 deg ( half angle). The USA prop is 1.77 deg

M |

miro

Senior Member

Username: miro

Post Number: 936

Registered: 11-2001

| | Posted on Sunday, October 08, 2017 - 08:31 pm: |

|

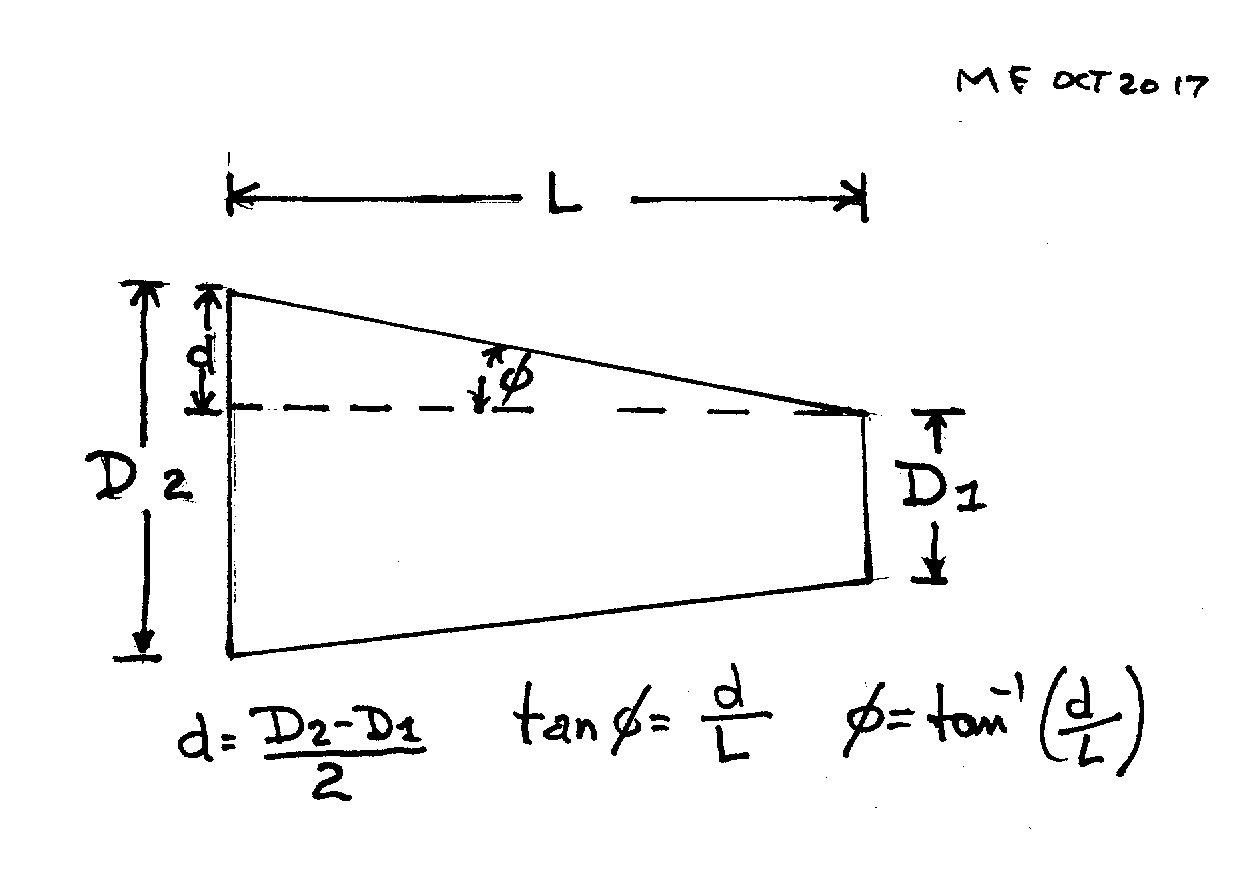

With a prop, there are only 3 dimensions I can measure - the length (L) , the big diameter ( D2) and the small diameter ( D1)

I use these to calculate the half angle (theta) that I need when I am cutting the taper.

Scientific calculators have the inverse Tangent function .

I measure the diameters and length within about 2 or 3 thou so I figure the half angle is pretty close to what I need.

Miro

I've used this quite successfully previously.

On fussy tapers that matter, I'll lap them into the final fit. |

ernie

Senior Member

Username: ernie

Post Number: 2407

Registered: 01-2002

| | Posted on Monday, October 09, 2017 - 08:13 am: |

|

Here is more info from a Google search

There are more than Miro mentions above.

My launch and all the shafts and props I have laying around here are 1 in 16 which is 1 degree 47' minutes 23" seconds. This is S.A.E. Specification J755.

A bunch of the stuff I have came from Newfoundland and was behind and Acadia or Atlantic M and B.

The 2 shafts that I made I cut at 2 deg. I calculated this from the compound on my lathe when taking a very light cut that just barely cut the entire taper of a shaft that fit the prop I was going to use. Oops but then I did lap them in.

Thanks to Miro for bringing this up. There is lots of good info out there and some really nice reference charts available.

Hope this helps

Ernie

http://www.propellerpages.com/?c=tech_info&f=tapers

https://www.techboat.fr/Bibliotheque/SAE_%20dimension.pdf

https://www.propshopinc.com/blog/Information-and-Chart-to-Determine-Prop-Bore-Si ze-Shaft-Diameter-Taper-bp11.html |

miro

Senior Member

Username: miro

Post Number: 937

Registered: 11-2001

| | Posted on Monday, October 09, 2017 - 07:58 pm: |

|

Ernie - that's good stuff - now that I've done a lot of the fussing with the tapers I really understand what they're talking about.

Here's a video of the fantail now running a lefthand prop - had a bit of a challenge with my selfie stick though :-}.

Went over to see the Dippy Doctor - about a 25 minute run over open water - didn't miss a beat.

And it got me home OK too.

At Dippy Doc's place I bump started it with a push on the flywheel rather than pulling it - like I've seen some of the Cajun gang do - and she fired right up.

Next step is to learn reversing on the switch.

https://youtu.be/GrFqtVhbLQM

miro |

ernie

Senior Member

Username: ernie

Post Number: 2408

Registered: 01-2002

| | Posted on Tuesday, October 10, 2017 - 07:09 am: |

|

Neat |