|

| Who makes reproduction piston? |

| Author |

Message |

kayak

Senior Member

Username: kayak

Post Number: 112

Registered: 06-2016

| | Posted on Monday, February 20, 2017 - 09:34 pm: |

|

I did a search and did not find the info. If I ever needed an oversize, or under-size piston for an old marine single, who is a good source? Most mainstream piston companies have a min order of 4. Anyone have a good source ?

Thanks |

kayak

Senior Member

Username: kayak

Post Number: 113

Registered: 06-2016

| | Posted on Wednesday, February 22, 2017 - 05:07 pm: |

|

anyone? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1281

Registered: 07-2002

| | Posted on Wednesday, February 22, 2017 - 07:26 pm: |

|

The Palmer Baby Husky used a piston compatible with a Ford flat head, it's possible your YT1 would match a piston out there, possibly a tractor or maybe something like a Wisconsin. Some of the old piston catalogs had specs in them. The next option wold be to make a pattern and have one cast. |

kayak

Senior Member

Username: kayak

Post Number: 126

Registered: 06-2016

| | Posted on Tuesday, March 14, 2017 - 11:41 pm: |

|

Is it an option to obtain aluminum round 3" diameter and use bridgeport to machine the inside and drill for the wrist pin, and turn the outside down for ring grooves etc, like the Barker that George pointed me to in the other thread?

Have others done that and run the engine successfully for many hours and if so what type of aluminum? |

johnny

Senior Member

Username: johnny

Post Number: 570

Registered: 03-2006

| | Posted on Wednesday, March 15, 2017 - 08:17 pm: |

|

You might give Mark Bruno out of Placerville California a try. Has odds & in's for antique engines but perhaps known mostly for his reproduction cast iron carts he sells. I know he has cast plugs for 5" to 6" inch bore. He may have others. He is own Ebay or you can deal with him direct. I have purchased a few of his carts over the years and they are of great qaulity.

530-621-1458

[email protected]

http://www.ebay.com/itm/ANTIQUE-OLD-HIT-MISS-GAS-ENGINE-CAST-IRON-PISTON-BLANK-C ASTING-/252696929684?hash=item3ad5e92594:g:EI0AAOSwEjFXfrkG |

kayak

Senior Member

Username: kayak

Post Number: 127

Registered: 06-2016

| | Posted on Wednesday, March 15, 2017 - 10:54 pm: |

|

thanks johnny, email sent. not sure if he works with aluminum, but we'll see. |

kayak

Senior Member

Username: kayak

Post Number: 128

Registered: 06-2016

| | Posted on Thursday, March 16, 2017 - 10:17 am: |

|

ok just an update, he got back to me (isnt that a nice thing!) but doesnt make anything in aluminum. what he does make in cast iron looks nice.

need to find someone who has turned a piston from round aluminum. OR pay all the money at a major maker to satisfy the min order. |

keith

Senior Member

Username: keith

Post Number: 485

Registered: 02-2002

| | Posted on Thursday, March 16, 2017 - 10:23 pm: |

|

Kayak. You have changed your login name several times. That because other people on this site have grown tired of your ranting. You have been given serious, objective, informative advice. All of which you find insufficient to solve your self created issues. It's been obvious you are smarter and have more of an analytical mind than those on this site. My advice to you is to move on. Find another place that can give you good and appropriate advice. Advice that is superior to your own self-supposed knowledge. |

kayak

Senior Member

Username: kayak

Post Number: 129

Registered: 06-2016

| | Posted on Thursday, March 16, 2017 - 11:45 pm: |

|

Seriously, what rant? As to my remark about people not getting back, I have 4 piston inquiries out to piston suppliers, only two came back. I emailed the suggested piston ring person, no reply. Maybe his account changed? It is still frustrating when making inquiry and they dont reply. (Most do) If you want to call that a rant, whatever.

I have no idea why anyone would become "tired" of my efforts to restore this engine to proper specs.

as to your rant about my name change, I changed my name for only one reason, due to the grief I was getting while trying to get help (which was NOT offered) in removing the YT flywheel. So I bagged out closed the account, and said why. I received an apology off line and came back. But the old name wouldn't work so I made a new one and that one stopped working and the board admin wasn't available. Eventually I got the account sorted out.

Just what advice should I follow? That has not been decided yet. I am gathering some options to solve the 20 over cylinder wear and related oil control.

Ernie suggests to replace the rings (which i cant obtain so far) and run it, others have discussed some re-sleeving options, JB has talked about the benefits of aluminum piston, Dick spoke about adjusting the breather assembly. All great advice for me and others.

So applying my "analytical skills" keith which you credit me with, I would suggest that a lot of good advice has been added to this site as I work through the cylinder options on my YT.

I am not the only person with a YT, or any old water cooled single. When future visitors see these posts, they may enjoy the reading. right up until they see your post, keith. Why don't you be positive and helpful? |

dick_briggs

Member

Username: dick_briggs

Post Number: 17

Registered: 02-2015

| | Posted on Friday, March 17, 2017 - 04:23 pm: |

|

I for one appreciate this threads (I have a YT-1) and all the others. I look forward to reading the diverse opinions, options, and possible solutions to a myriad of problems. I always learn something (many things actually) from this site and I for one wouldn't want anyone to ever feel intimidated about asking and even re-asking a question, no matter how basic. There is always more to learn about these engines we care so much about.

Dick Briggs |

kayak

Senior Member

Username: kayak

Post Number: 131

Registered: 06-2016

| | Posted on Friday, March 17, 2017 - 10:56 pm: |

|

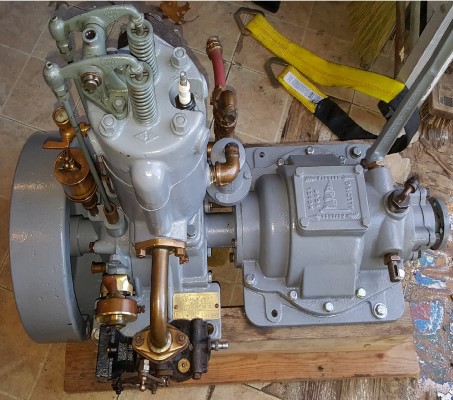

Thanks Dick. Also, I misspoke above. I reviewed the flywheel thread and there actually was some good help put forward along with some differing advice. But all came out very well in the end and the YT is now beautiful. Some members here go back 15 years and decades of experience. But I'm pretty new at all this. What's easy to some is brand new over here. |

kayak

Senior Member

Username: kayak

Post Number: 133

Registered: 06-2016

| | Posted on Sunday, March 19, 2017 - 01:21 am: |

|

Getting back on track, I am developing options for getting a reproduction piston in aluminum. If a source and a piston turns up, I will update this thread with that info for others.

BTW, I will share a neat option that I was told about. If the cylinder bore is worn like mine, get it trued up and honed and then take the cast iron piston, clean it up, and run a wide bead of braze around the skirt but above where it leaves the bore (so the braze stays in the bore) and another ring just below the oil ring. Have that turned to the new bore size minus your clearance (.005"). Get oversize rings and gap them appropriately. Also check the ring groove clearance - may need spacers along with the rings - and now, according to my source, you have a piston that wont rattle, rings that will seal, and a straight bore with the least material removed. Not sure how far you can go with this in thousanths.

This is 2nd hand info I have not obviously done it. But it sounds good and from highly credible source.

Also, my engine machinist reminded that a piston can be knurled as well. That's a more common practice and not sure if it is for aluminum only or also cast iron.

Regarding rings, George C provided a source for those in my YT oil thread (Otto ringspacers.com) and he has them, but if not, ring spacers can be used along with a thinner, common newer ring if thats all thats available.

But on this issue I am looking to have a nice thick sleeve properly installed (which is according to another very good source of advice, to say light interference fit to avoid cracking the old cylinder) with a 'lock stop' at the bottom, in other words stop boring 1/4" before the bottom of the cylinder to create a land for the sleeve to stop against, and make a head gasket that will be on top of the sleeve, so the sleeve is captured between the head gasket and the lock stop. Then it wont move. As to how tight, I was told that if the cylinder is heated and the sleeve right out of a freezer, it should press in by hand.

The caution I was given was that an everyday engine shop is used to modern engines with fresh strong cast iron and they will machine a tight fit and press the sleeve in, which may crack an old corroded antique cylinder.

In a way I am glad the cylinder is a bit worn because I have learned a heck of a lot from that from the experienced folks here and elsewhere.

For example George suggested in the other thread to bore a little less for a smaller sleeve then bore that sleeve to the original piston (which can be dressed down slightly and trued up). This results in a thinner sleeve, but also less cylinder material removed.

But since I am going to have an aluminum piston anyway, may was well really minimize the boring and keep the thick sleeve, I'll just have the new aluminum piston made a little smaller.

With any luck, this YT will have a nice thick cylinder sleeve and a nice light reasonably priced aluminum piston and be at factory tolerances with great compression and oil control.

Didnt mean to write a book but this all new to me so it will probably be new to someone else as well. |

ernie

Senior Member

Username: ernie

Post Number: 2371

Registered: 01-2002

| | Posted on Sunday, March 19, 2017 - 12:33 pm: |

|

Kayak,

Just for your info...

If you want it...

Before you go and make the mistake of putting an aluminum piston in the YT consider the following.

JB said "on a non counter weighted engine they run smoother" End Quote

Your engine is counter weighted to run with a 2 pound piston. What will an aluminum one weigh? 1 Pound?

What is the gain that you anticipate?

Palmer actually went through the trials and tribulations to put an aluminum piston in an engine (ZR) that was designed to have a cast iron piston.

A quote from the Palmer engineer " this was one of the stupidest things we ever wasted money on" End quote

There were balance problems as well as piston to cylinder clearance problems.

With enough piston to cylinder clearance so it wouldn't seize when hot the engine knocked badly when cold.

As to balance another Palmer quote " what did we do that for? It was designed to run 700 RPM and balanced to do that. And it did it extremely well" End quote

On a ZR engine the iron piston weighs just shy of 10 pounds. The aluminum ZR piston weighs just over 5 pounds.

Note in the pics the aluminum piston is a real engineered casting, not one machined from aluminum billet. Also note the cuts in the skirt that Palmer made after the fact to try to keep it from seizing when hot and not knock badly when cold.

Save the time and money and use what Palmer designed it to have.

Your last line above

"at factory tolerances" End quote.

Good luck with that once it gets hot...

|

robert

Senior Member

Username: robert

Post Number: 846

Registered: 07-2003

| | Posted on Sunday, March 19, 2017 - 07:25 pm: |

|

Amen Keith. Some of you have the patience of Job. By the way, how many IDs can a member have concurrently? |

ernie

Senior Member

Username: ernie

Post Number: 2372

Registered: 01-2002

| | Posted on Sunday, March 19, 2017 - 08:07 pm: |

|

Robert that number would be set by Andrew. As it is now if believe it is only 1. However one can delete their account and then create another with a different user name. Over the years there have been a few members that have done that.

As to the "patience of a Saint" some of us are just hoping that this YT1 will eventually once again be a good running engine. |

kayak

Senior Member

Username: kayak

Post Number: 134

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 02:13 am: |

|

I cant believe anyone would condone the hateful rant by keith, and cite biblical terms no less (amen, job, saint). Unreal. This doesnt belong in a technical piston thread. If I were admin I would remove that keith post, the robert post, and message those members. It contributes nothing to a piston options topic and is an embarrassment to this board to allow that kind of slander.

As to patience of job, someone elses small old engine is taking too long for you robert in canada? really? Remember I am new at this.

now as to ernie, as usual ernie shares some incredible insight. thank you. GREAT piston info. as to how good this engine was when you sold it to me, and I do really like it, lets look at it before and after. and I should mention that the main bearing oil grooves were clogged, the trans was filled with milky sludge, and developing such rust that there was no neutral, and oil seals leaked, the case was peeling and corroded. all things that supposed old engine lovers would support fixing, right? and to start fixing them, the flywheel needed to come off first.

also, you did tell me that I do "nice work" (thanks). and you also have stated that JB is an expert. the same JB who brought up the aluminum piston option. and yes the crank can be re-balanced by my engine machinist, I asked. and yes I saw JB's mention of having to take .002" more diameter off the top of an aluminum replacement piston to find the expansion sweet spot. But it ran. As to "rattling" or "knocking" well yes these motors run cool, and the piston runs hot. So u need more initial clearance. How long to expand and stop piston knocking? A minute? less?

The cylinder is in fact .020" over with a big ring gap. maybe your right I should install oversize rings, hone it, and run it. but discussing options seems like an appropriate thing on a ... discussion board... agree?

a few of you people are trying to take the fun right out of this. the question is why?

|

kayak

Senior Member

Username: kayak

Post Number: 135

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 02:23 am: |

|

couple more. the cases were sandblasted and epoxy coated.

|

kayak

Senior Member

Username: kayak

Post Number: 136

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 09:19 am: |

|

Some great info about piston expansion cast iron versus aluminum in old Model T engine found here:

http://www.antiqueautoranch.com/montana500/speedpiston.html |

kayak

Senior Member

Username: kayak

Post Number: 137

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 09:34 am: |

|

More here, the very long post by Ivan Saxton on piston material issues is especially interesting:

http://forums.aaca.org/topic/145867-aluminum-pistons-better-than-iron/ |

kayak

Senior Member

Username: kayak

Post Number: 138

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 09:59 am: |

|

And this one from smokestak. Not disagreeing with either position, but aluminum retrofit seems to have majority favor in these discusions which certainly supports JB's advice as being not at all wrong. (And ernie is correct too to consider expansion and balance issues).

https://www.smokstak.com/forum/showthread.php?t=27495 |

kayak

Senior Member

Username: kayak

Post Number: 139

Registered: 06-2016

| | Posted on Monday, March 20, 2017 - 10:06 am: |

|

And I should add to see in the smokestack discussion the individual who is casting his own pistons in the backyard with good success, and even pouring aluminum around an iron piston to make it bigger, re-purposing junkyard diesel pistons in hit and miss engines, and a couple other neat tricks not that I would ever consider any of those choices but it's interesting the people are doing them and getting good running engines and I thought worth adding to this piston discussion. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 1291

Registered: 07-2002

| | Posted on Monday, March 20, 2017 - 10:07 pm: |

|

If I were on a budget and couldn't machine my own piston I would run the cast iron. You might gain 10% hp, 2.2 instead of 2, that won't get your boat up on plane. If the cylinder is corrected, put it together, you can always change the piston later if you want to. |

keith

Senior Member

Username: keith

Post Number: 486

Registered: 02-2002

| | Posted on Tuesday, March 21, 2017 - 12:32 am: |

|

JB. You have to understand, your experience, skill-set and list of all your mechanical accomplishments don't carry any weight with an idiot like Kayak. Neither does any of the other suggested considerations by others, far more experienced and far better capable to diagnose and correct issues, than he. You have to understand he, after reading and comprehending all the online professed successes, will now be able to cast his own piston in his own back yard. This because no one has given him viable solutions to his problems. He, incorrectly, thinks I have admitted that he has an analytical mind. I said that in jest. This because, for all the help that has been given by others on this site, his analytical mind has debunked and rejected those sincere offers of assistance and has been unable to resolve his issues. He is still waiting for a viable solution to his issues. He, obviously, hasn't been able to analyze and resolve his issues.

For those that think this thread may help them with their own problems, consider this. Those that have come to this site and made suggestions and remedies to helped others, will stop if they find the recipients only response is to denigrate the corrective action and propose off the wall remedies. By the way they haven't happened. As far as his skill set, it would appear he is only capable of paint and enticing others to do his work. |

henrym1959

New member

Username: henrym1959

Post Number: 1

Registered: 03-2017

| | Posted on Wednesday, March 22, 2017 - 10:07 am: |

|

I like kayak's work and as someone who is up front about being new at this, he is very careful and deliberate. He started this topic with a single question, where would the more experienced source a reproduction piston. He was looking for options, and I dont see that question fully answered. Ernie should not describe an engine with a 20 over bore wear and rusting sludge for trans oil as a good running engine, implying that kayak somehow should not have serviced it . I did not see kayak complain about that, he fixed it and did a great job so far, and the pictures he's shared show he did it all himself and it was a lot more work than paint. I've not seen a newcomer more respectful of this legacy machinery.

Keith's personal remarks are especially troubling. I went to kayak's other topics and did not see keith offering help or information there either. I will let that and his post speak for itself.

In short, the OP asked where to source a repro piston and was told by some that he didnt know what he was doing, don't do it, and implied he somehow ruined the YT when he actually is saving it.

Keep on kayak, you'll get there. Post the updates. |

dick_briggs

Member

Username: dick_briggs

Post Number: 18

Registered: 02-2015

| | Posted on Wednesday, March 22, 2017 - 11:24 am: |

|

Thank you Henrym; I agree completely. I have held off responding until I cooled off a bit. I don't understand the venom expressed in this thread, especially since those most knowledgeable here, like JB and Ernie, continue to offer their advice so freely and without complaint. I might suggest that if one doesn't like the way a thread is going or who is posting it, just don't read it. But at the very least, don't trash someone.

Indeed, keep on kayak. I for one learn a lot from these interactions.

Dick Briggs |

robert

Senior Member

Username: robert

Post Number: 852

Registered: 07-2003

| | Posted on Wednesday, March 22, 2017 - 03:57 pm: |

|

Dick, that's because you're not able to read the deleted posts by this member who has had four if not five user IDs and currently has two, if not three going simultaneously. There was an unpleasantly childish outburst by this gent immediately after he joined this forum, with snippy remarks about "grumpy old men" etc. that were deleted by our long-suffering moderator. Those same "old men" are now politely holding his hand and humoring his need for attention. I don't believe there has ever been any apology given either.

As I said before, I admire the patience of those who do indeed have the knowledge here and are freely sharing it despite the previous insults and childishness directed at them.

Some psychologies, apart from constantly needing to be the center of attention, particularly enjoy stirring things up and setting people against each other. Unlike engines, such problems can rarely be fixed. |

ernie

Senior Member

Username: ernie

Post Number: 2373

Registered: 01-2002

| | Posted on Wednesday, March 22, 2017 - 04:45 pm: |

|

Gents

This discussion board is about old marine engines and NOT about the members.

Lest we all forget none of us as in NOT any pay anything for the privilege of using this board.

If the moderator has to keep stepping in and editing or deleting posts all it would take is a mouse click or two and it is ALL gone.

Please lets not even go near that. Just think of the history that would be out of the public domain or no longer easily accessed.

Now about the comment from Henrym1959 about me.

You buy an old engine that runs good.

It was NOT sold as a new or perfect engine. The ONLY claim I made as to its condition was that it ran good. In fact it ran good enough I almost put it in a boat.

Now you take that engine all apart and give it a bath and an Aerosol overhaul. What is an aerosol overhaul you say? Simply put a coat of paint. Now as to the fact that for some reason it barfs oil out of the breather. Well a coat of paint does NOT a new engine make.

Why wasn't the cylinder measured when it was apart the first time.

Kayak was told by several of us several times to adjust the breather as per Dick Days instructions and run it. Did that ever get done to see if it still barfs oil?

If we don't get a reply to a post in a timely manner lets all remember all of us have lives, Old engines and OME are in most cases a very small part of each and everyone's schedules.

Lack of a reply does not need a comment "anyone" as the only content in a post.

In most cases we have access to everyone's e-mail. Consider sending an e-mail direct to a member or members as a much more polite way of going "yo hey" need some help here.

How many times have we looked back into older posts and went "oh gee I forgot to answer that question I was asked."

I found one the a month or so ago that was asked over 10 years ago. I hope the person that asked the question is still an active member and saw my answer.

So Henrym I see this is your first post. Hopefully you have been reading OME for a while and realize that the nature of what has been posted about one certain Palmer YT engine isn't the norm.

By the way it sure looks better now than when I owned it.

Bottom line lets stop the off topic flames and keep it to just engines old boats and the like.

Henrym welcome aboard

Do you have an engine or engines?

If you are on the US east coast hopefully we can get to meet you at either the Calvert,MD show in May or the Mystic Seaport show in August.

Don't be shy,share what you have with us and please don't consider this the norm.

Thanks for reading the essay

Ernie |

narrabay

New member

Username: narrabay

Post Number: 1

Registered: 05-2016

| | Posted on Wednesday, March 22, 2017 - 06:28 pm: |

|

OK bear with me, since this is off the piston sources topic anyway I would like to clear the air on a couple things. Sorry a bit long. If I wasnt in my slow work season, wouldnt even have the time.

Yes it was a good running (if dirty and rusty) motor when I purchased it. I ran it very briefly before taking it apart and don't recall much oil from the breather. Ernie is correct there.

But it has had far more than paint so please lets not belittle my effort. Not to mention I now *really* know the YT. We see the gunk inside, and I believe I mentioned the oil grooves clogged with sludge, and the oil seals shot so it needed a disassembly and inspection. It did not need a machine shop overhaul but it did need what it got, and that was way more than "paint".

As to the internals (remember this is a simple one cylinder engine not much more complex than on our lawn mower, really) the bearings look good and journals not scored or worn. As to why the cylinder was not checked, it was because it did run well when I got it and Ernie had replaced the cylinder. I have enough respect for him not to think it needed checking. I did see the scoring on the bore but again, it ran.

Fast forward it was reassembled and there was lot of blow by and even oil above the piston after a short 10 mins or so run. I told Ernie that I think simply the rings didnt re-seat. I probably should have broke the glaze with a hone.

But by the time I had the cylinder off, I did decide to really look into things and had the bore measured down the street at the engine machinist. Ernie advised me to check the ring gap and that was kind of big too. So we have some wear.

At that point, I was not about to bolt everything back together and try the breather adjustment (which, the adjuster IIRC was not changed anyway), only to then come apart again and address the cylinder. Call it OCD, or recollections from my past as a junior mechanic, but restoring the bore and replacing the rings seemed the right thing to do.

Any conversations about the cylinder in the two topics (this one was supposed to be only where to get a piston) generated a number of options, I think 5 choices.

-Install fresh "oversize" rings and run it (presumably hone it too)

-Install Ernie's oversize YT piston (where does he GET this stuff?)

-Minimum bore it, Sleeve it and have an undersize piston made (that uses off the shelf rings)

-Sleeve it to OEM 3" bore

-Sleeve it "half way" and re-bore the sleeve to 3" (removes less original material) (I will be doing this one, sleeve is ordered)

It was interesting to learn about the pros and cons of changing to an aluminum piston. And those postings will surely help others in the future.

Now, as to the history lesson from robert. His information is mostly wrong. I did have to get ultimately three names on here (not 4 or 5), and that is my fault. I felt slighted when asking about the flywheel removal, and some rude posts on the test fit up topic (1 ruined motor and boat, etc). If you read the posts, I am generally appreciative and polite. But there were some not so helpful remarks, and I did in fact get a little mad and called everybody a disgruntled old Hoover Voter which was halfway a joke anyway, if you know your history Herbert Hoover was a renowned engineer. But I was mad and deleted my own account. Which was wrong to do. I should have just let it go.

Someone did in fact apologize, and I felt bad too about the Hoover remark. So I re-joined, but had to use a new name, the old wouldn't work. Of course I picked Herbert C Hoover which I was kind of making fun of myself. Well almost right away I lost the password, could not get ahold of admin, and created a third, Kayak, and continued on with the YT and the Dispro, two cool projects which would not be as possible without OME. Ernie sold me the YT (it's great motor for this project), and Miro who I thought at first was pulling my leg, sold me on the Dispro,. (Thank you Miro). Subsequently I got the old name working which I can use. But it is apparent that it's me anyway.

As to deleted posts, I dont recall any of mine except I requested the flywheel thread posts after the flywheel came off be deleted, including the Herbert Hoover remark, to preserve the topic as helpful. At MY request, the topic was pruned after the success post, at my request.

As to Ernie's concern about the vast knowledge wealth here, I agree. I belong to another technical site for many years now and we have discussed that. As a result, it's archives are preserved in multiple places through backup. Perhaps that is something Ernie, George, JB and the others can bring up for the new people 20 years from now to benefit from.

I take my responsibility for not letting things go and not being smart and keeping quiet.

The two topics here, anyone with concerns please read my contributions:

http://www.oldmarineengine.com/discus/messages/1/271739.html

http://www.oldmarineengine.com/discus/messages/1/271952.html

So agreeing with Ernie, if we could possibly, in any way shape or form, clear this up. If anyone has a concern about my participation, just email me off line please. I will listen. Everyone would be better off.

}} |

robert

Senior Member

Username: robert

Post Number: 853

Registered: 07-2003

| | Posted on Wednesday, March 22, 2017 - 07:30 pm: |

|

Your user IDs for the record:

1. (deleted after tantrum)

2. herbertclarkhoover

3. herbertchoover

4. narrabay

5. kayak

6. kayakchris(?)

Five for certain, probably six, not "two or three". Your account of what occurred is a verbose dissimulation, just like your account of your user IDs. (An incident I had no part in, in case anyone wonders.)

You're still logging in and posting as narrabay as recently as a few days ago. Why the hide and seek?

Are you kayakchris as well? And BTW, your IP address is available to the moderator. ;-) |

keith

Senior Member

Username: keith

Post Number: 487

Registered: 02-2002

| | Posted on Wednesday, March 22, 2017 - 08:37 pm: |

|

robert

add "henrym1959" to the list of aliases. |

billschaller

Senior Member

Username: billschaller

Post Number: 682

Registered: 12-2003

| | Posted on Wednesday, March 22, 2017 - 09:30 pm: |

|

It's a good thing this isn't a 6 or 8 cylinder motor.

I didn't go back and read it all, but why not knurl the piston, and put in wider rings?

or, sleeve the piston? |

narrabay

New member

Username: narrabay

Post Number: 2

Registered: 05-2016

| | Posted on Wednesday, March 22, 2017 - 09:52 pm: |

|

hi bill, my machinist said he would need to bore 40 over to get it straight and it is a cast iron piston and he seemed to imply he couldnt knurl that much.

nonetheless, I've decided sleeve the cylinder the way george and jb have suggested which is bore it basically to 3 and 1/16, sleeve with a 1/8 sleeve and then bore the sleeve back to 3" bore. that sleeve is on order now.

I never heard of sleeving the piston, interesting. although I was told about brazing the skirt with two rings and having that turned, which is also interesting.

and yes ernie suggested to if I remember right, hone it and install oversize rings. but its going to be sleeved now so I should be all set.

this topic started was when I was considering a nice thick sleeve with minimum boring on the old cylinder, then getting a slightly undersize aluminum piston made. so this topic was simply asking for sources I could write to and inquire on pricing etc. but that is moot for now due to the sleeve plans.

IF I had gone to aluminum, there were two really appealing benefits. one was reduced piston weight. my crankshaft is counterweighted but my shop said he could easily balance it back to the lighter piston. the second is that rings would be more available as the ring grooves would be cut to narrow, modern dimension.

I was told (remember I'm new at this) that the lighter piston would result in less vibration. while the counterweights balance the heavy piston in the up and down motion, they have nothing working against them side to side, so thats the "secondary vibration" which especially (I was told) would reduce with lighter counterweights.

but using the original piston keeps the engine more original, is easier, cheaper, and while I was really fearful about cutting too much from the bore, george and jb got me convinced not to worry and do the "bored-sleeve" method. I have not even discussed it with my shop but he should be able to do that. |

billschaller

Senior Member

Username: billschaller

Post Number: 683

Registered: 12-2003

| | Posted on Wednesday, March 22, 2017 - 10:56 pm: |

|

I would do whatever JB suggests. But, for old slow speed engines with large hard to replace pistons, spray welding or piston sleeving can be done.

https://www.smokstak.com/forum/showthread.php?t=42905 |

doug11k

Senior Member

Username: doug11k

Post Number: 89

Registered: 12-2003

| | Posted on Monday, March 27, 2017 - 08:58 pm: |

|

Have not been on here much lately, but I'm with Keith!! |

narrabay

Member

Username: narrabay

Post Number: 6

Registered: 05-2016

| | Posted on Monday, March 27, 2017 - 11:03 pm: |

|

On the piston sources topic of this thread, not going aluminum for the time being, but to answer the original question, so far, Ross and Diamond have responded (yes I know they are mainly car piston companies). The cost is about $600 for a minimum order of four (150/ea) at both makers. I have been given several more names and plan to accumulate as many options as possible, and list them here.

The most promising is from Otto, but I have not gotten a price yet. This is academic for now because the cast iron vs aluminum discussion seems to conclude not much benefit to switching, and my piston is in good shape, however it would be good to have options. And this topic is really only for listing sources to get an aluminum reproduction (or substitute) piston for an old engine.

http://www.ringspacers.com/piston.htm |

|

|

|

|